Benefits of Converting Metal Parts to Plastic Injection Molded Parts

During World War II, when metal was in short supply and manufacturing speed took precedence over product life, plastic molded parts began to be used instead of metal parts. By the 1950s, stronger and more durable resins and plastics made plastic parts a viable option. Since then, the quality of plastic has continued to improve. Plastic injection molded parts are now the smart choice for almost every industry. While injection molding was born out of necessity, many industries are turning to plastic injection molding instead of metal parts.

What are the benefits of injection molding of parts

If your business currently uses metal parts and you have no real complaints, converting to plastic injection molded parts may seem like a hassle. However, take a look at some of the advantages of plastic injection molded parts and you may find conversions.

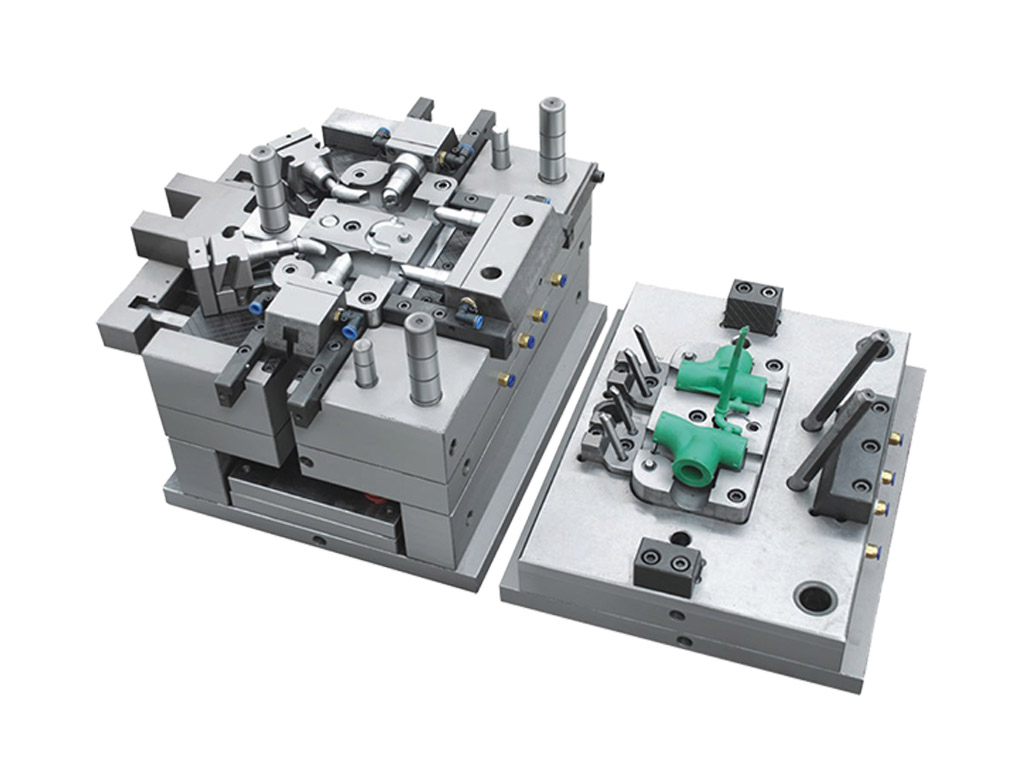

More design flexibility

for a good reason. While metal parts can be customized for many applications, they don’t give you nearly as many design options as plastic molded parts. Plastics add strength without adding weight, directly reinforce assets such as gussets or ribs during the molding process, and in many cases outperform metal parts.

The ability to mix materials in custom plastic parts enables you to produce a plastic that exactly meets your needs. You may need a plastic part that is safe to handle food or one that is particularly scratch-resistant. These and more options can be achieved through careful selection before shaping the material into the exact shape and size required.

better aesthetics

With plastic injection molded parts, you can create any look. They can be molded into a variety of colors, shapes, and sizes without losing their functionality. This is especially useful for people who make cars, boats, some electronics, furniture, appliances, or any other product where appearance is almost as important as function.

Production is faster

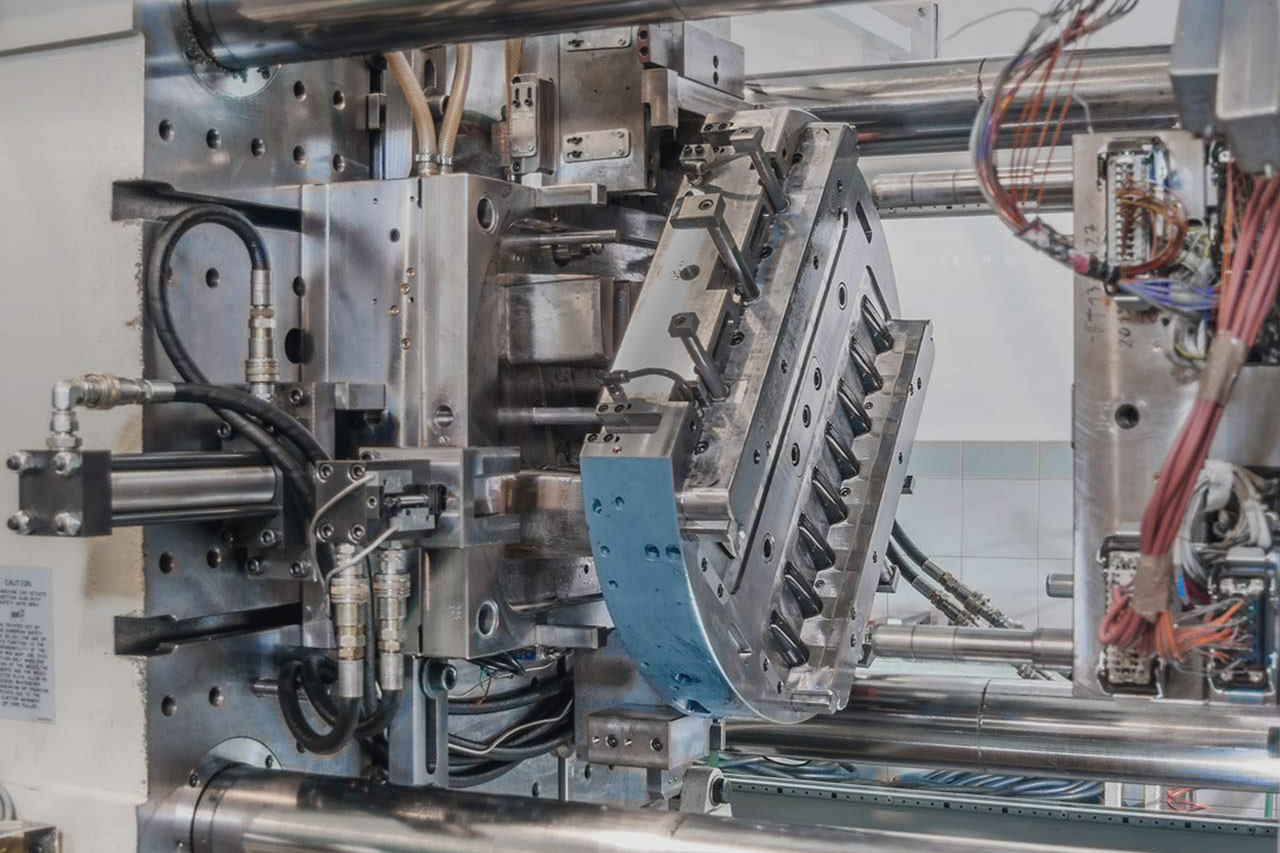

The process of making metal parts is not as accurate as plastic injection molding. Finished metal parts may not be the correct shape or size. Grinding or heating and shaping requires specialized tools and skilled craftsmen, and most importantly, time.

Plastic injection molded parts are manufactured faster than metal parts, and the molding accuracy reduces further grinding or reshaping of the finished part.

lower cost

Plastic parts are cheaper to manufacture and buy, easier to customize, and cheaper. To create a part with the exact size and shape required, manufacturers simply program the dimensions into the injection molding machine. In addition, the time and money saved by reducing the need for rework, grinding, sealant application, redesign, and product testing can lead to further savings.

How to determine if metal to plastic conversion is right for your company? While it saves time, energy, and money in the long run, the cost of converting metal parts to plastic parts will be enormous. You need to carefully consider whether the benefits of switching outweigh the initial cost.

You can start with these steps: Find a reputable plastic injection molding manufacturer and pick their heads. You might even give them a tour of your factory to see for yourself what parts you need and how to use them. They should then be able to advise you on cost, materials, and ease of conversion; check the feasibility of the parts you want to convert and the benefits of converting them. To see how many specific parts you need and whether it would be beneficial to reduce their weight or change the aesthetics, consider special considerations. These may include sterilization procedures, strength or flexibility, or the ability to withstand extreme temperatures

Analyze costs. While converting to plastic injection molded parts can be cost-effective in most applications, this is not always the case. You don’t need a lot of parts that are already fully available and may not be a worthwhile investment.

Ask the Experts

If you are looking for a reliable and reputable plastic injection molding manufacturer to help you get started, please contact http://www.tkbmold.com. We are an injection mold making and injection molding manufacturer located in Dongguan City, Guangdong Province, China. For 15 years we have been meeting the needs of our customers.

Previous:Common Steel and Performance Analysis Of Injection Mold

Next: Will you buy your injection moulds and products in China

-

Medical Molding Parts: Precision and Quality for Healthcare Products

2023-4-26

Medical molding parts are a crucial component in the healthcare industry, providing precision and quality in the product...

View details -

Manufacturing a Round Plastic Pail Mould: A Comprehensive Guide

2023-7-4

Introduction: Plastic pails are widely used containers in various industries, including food processing, chemicals, and ...

View details -

Automotive Molding Parts: Enhancing Efficiency and Precision in Manufacturing

2023-7-6

Introduction: The automotive industry has witnessed significant advancements in manufacturing processes over the years. ...

View details -

Designing a High-Quality Plastic Crate Mold for Large-Scale Storage Solutions

2023-6-17

Plastic crates have become an essential storage solution for a variety of industries. They are used in the transportatio...

View details -

Creating Quality Injection Molds for Manufacturing

2023-4-20

Injection molding is a popular manufacturing process that involves creating 3D objects by injecting molten plastic into ...

View details -

What is the Role of Injection Molding and What are the Benefits for the Manufacturing Industry?

2023-2-9

Injection molding is a process used to create objects from plastic materials. The process begins by heating the plastic ...

View details