About molding part for sweeper

To create a customized wholesale molding part for a sweeper, you will need to follow these steps:

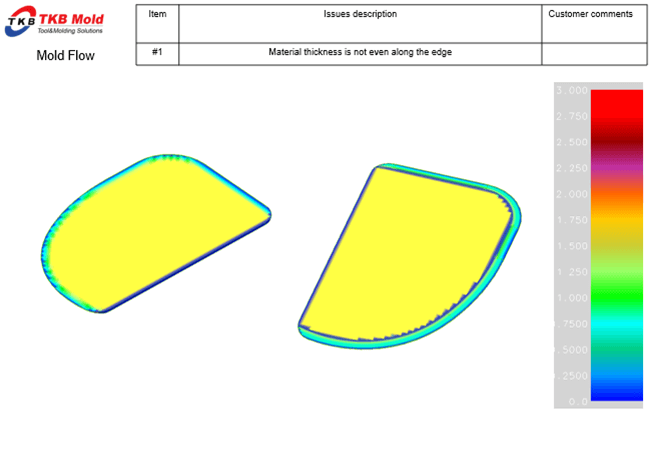

Determine the specifications of the molding part: Start by identifying the specific molding part that you need for your sweeper. Determine its size, shape, and material requirements, and any other details that are necessary for the part to function properly.

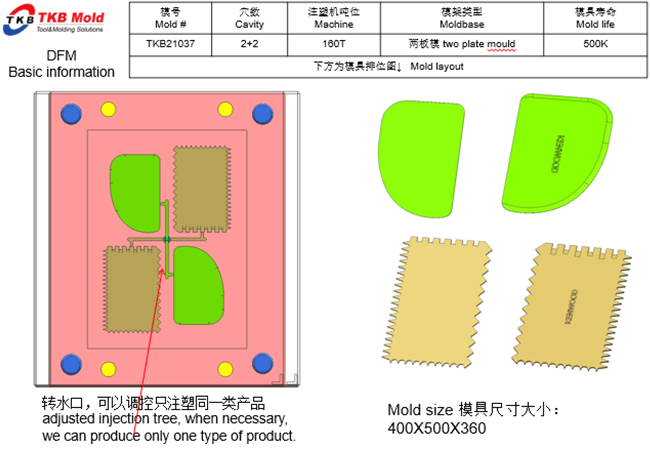

Design the part: Once you have the specifications for the molding part, you will need to create a design for it. This can be done using CAD (Computer-Aided Design) software or by working with a skilled designer who can create a 3D model of the part.

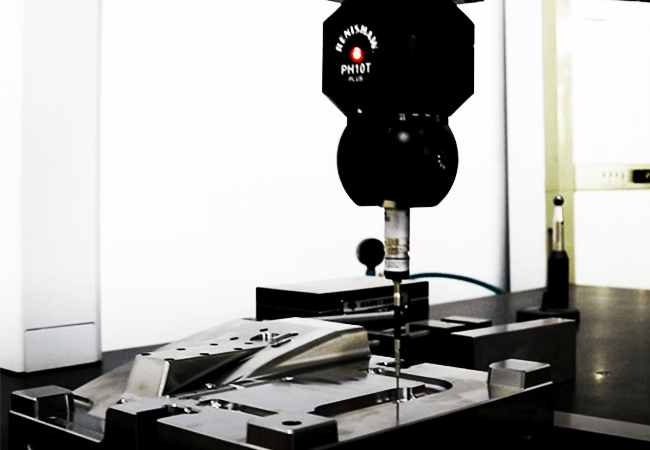

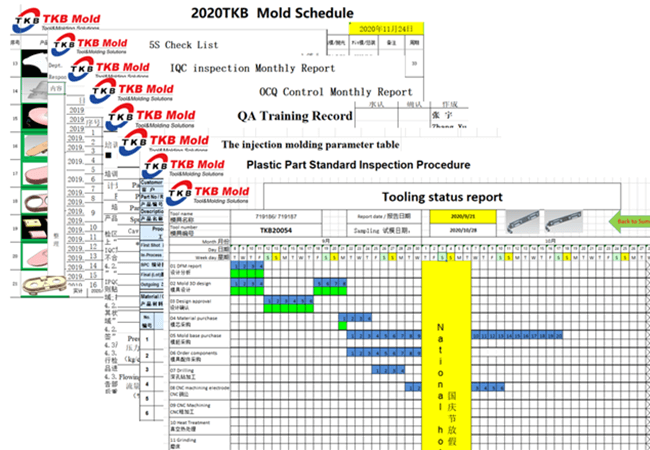

Select a manufacturer: Once you have a design for the part, you will need to find a manufacturer who can create it for you. Look for a manufacturer who has experience working with the type of material you need for your part, and who can create high-quality, precise parts.

Get a quote: Contact the manufacturer and provide them with the design for the part, along with any other relevant details. They should be able to provide you with a quote for the cost of manufacturing the part.

Order the parts: If you are satisfied with the quote and the manufacturer’s capabilities, you can place an order for the parts. Be sure to specify the quantity of parts you need, as well as any other details that are important to ensure that the parts are made exactly as you need them.

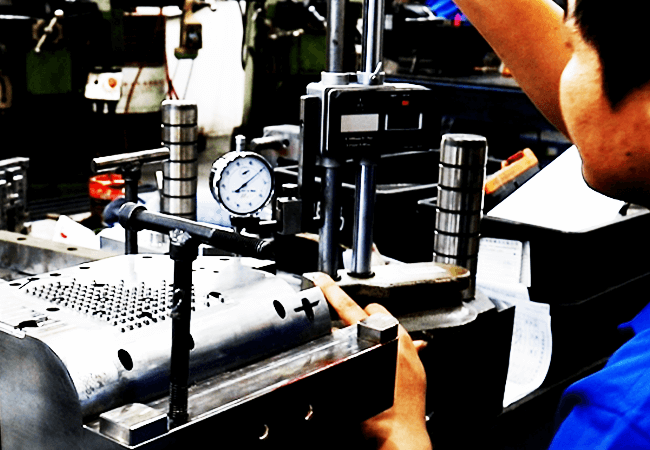

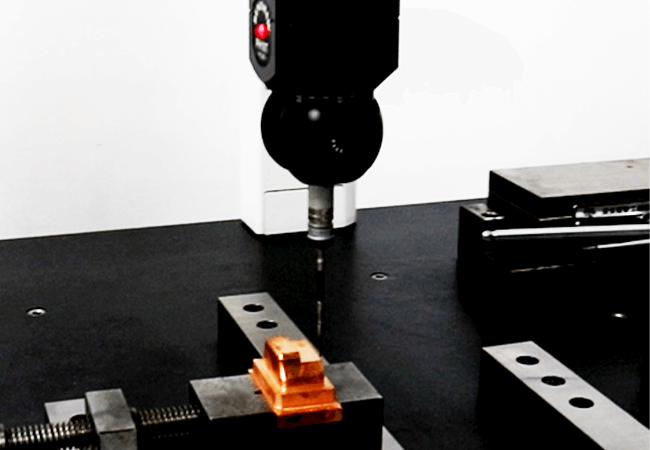

Quality control: Once the parts have been manufactured, it’s important to perform quality control checks to ensure that they meet your specifications. This can include inspecting the parts for defects or measuring them to make sure they meet the required dimensions.

By following these steps, you can create a customized wholesale molding part for your sweeper that meets your specific needs and is made to high-quality standards.