About large size mold Made in China

There are several reasons why one might choose to use large size molds made in China:

Cost-effectiveness: China has a reputation for offering competitive prices on molds due to their lower labor costs, which can help reduce the overall cost of production.

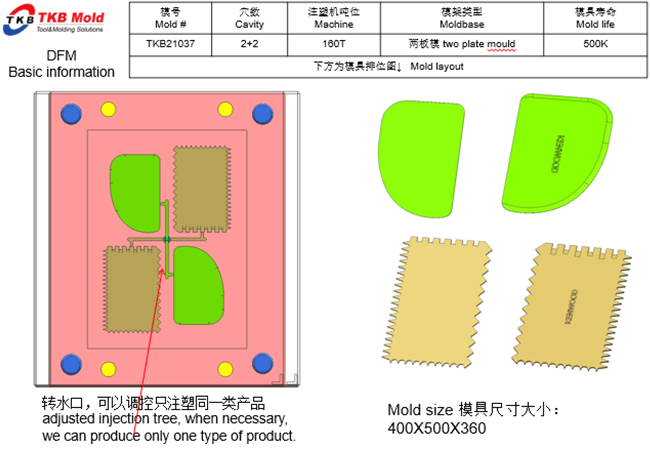

Wide variety of options: China has a large number of mold manufacturers, providing a wide range of options to choose from, including large size molds. This allows for greater flexibility and customization options.

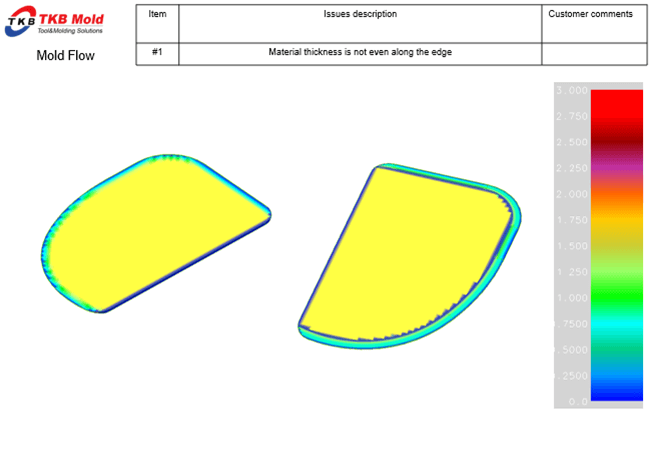

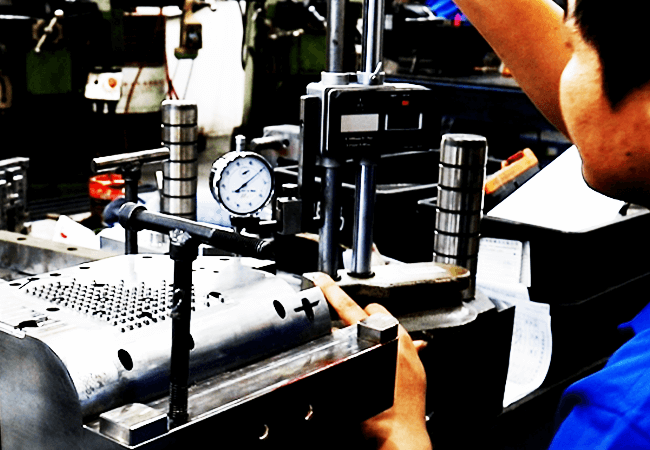

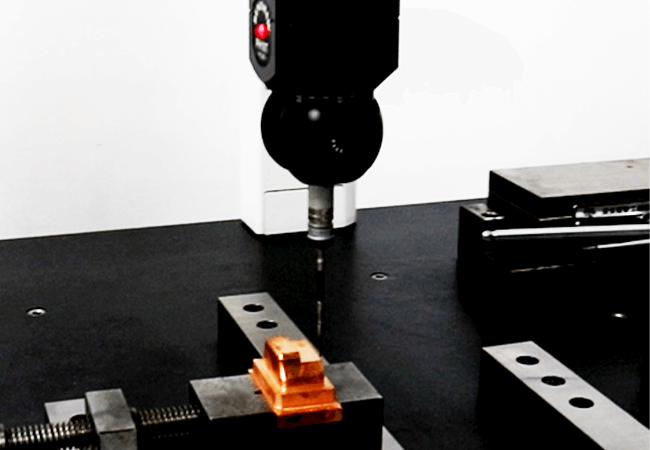

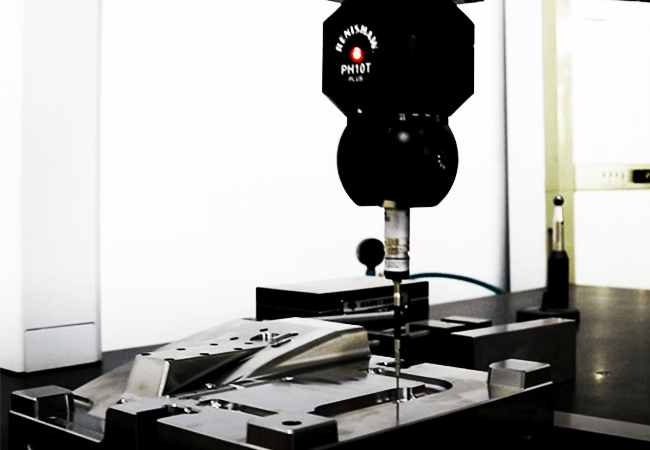

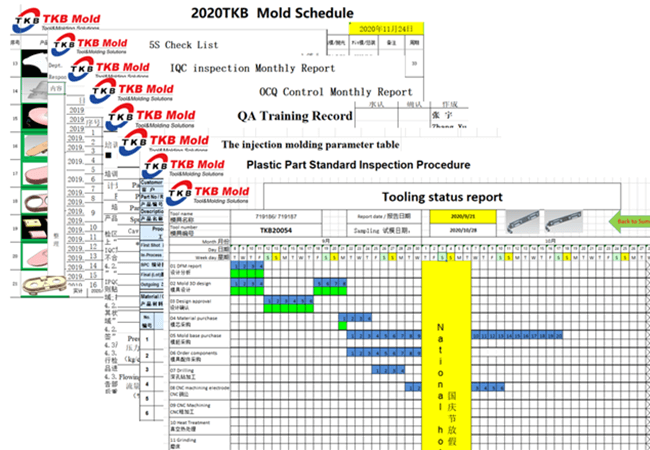

High-quality manufacturing: While China may have a reputation for producing low-quality goods, many Chinese mold manufacturers have invested heavily in their manufacturing processes and have implemented strict quality control measures to ensure the production of high-quality molds.

Experienced and skilled workforce: China has a large workforce with years of experience in mold manufacturing, which can help ensure the successful production of complex and large size molds.

Access to technology: Chinese mold manufacturers have access to the latest technology, which can help improve the precision and accuracy of the mold-making process.

Efficient production time: With the availability of skilled labor and access to advanced technology, Chinese mold manufacturers can produce large size molds quickly and efficiently.

However, it is important to do proper due diligence before choosing a mold manufacturer, whether in China or elsewhere, to ensure that they meet your specific requirements and quality standards.