அடிக்கடி கேட்கப்படும் கேள்விகள்/ Frequently Asked Questions

As a plastic mold and injection molding company in China, we prepared answers for following most frequent asked queries for you, for more queries are always be here for you.

CONTACT US

1. What info needed to get a correct mold quotation? How fast does it take to quote a project?

1)2D or 3D product drawing is needed for a mold quote;

2) If special requirement on mold steel, mold life, cavity quantity, hot runner requirement, part material, forecasted year quantity. Complete information will help to a most suitable cost effective, value added mold solution.

3) Normally take 2 working days to quote a new mold project seriously, and expedite quote is also available.

2. What’s the payment condition in TKB Mold?

1) New customer for mold: T/T 50% deposit, 50% against sample approval.

2) Mold modification: 100% upon sample approval.

3) Injection molding parts: 50% deposit, 50% before shipment.

4) VIP customer special terms: to be negotiated.

3. What’s the price terms/freight TKB mold will offer?

- Normally TKB will offer ex-work TKB price for injection mold and plastic parts.

- Free mold trial shotting samples free of charge and with freight to collect.

- VIP customer special terms: to be negotiated.

4. What’s lead-time for a plastic mold and injection molding processes?

- Injection mold lead-time counted from mold drawing approval and receipt of deposit to first mold trial(T1), and the difficulty of the molds determines how much time is needed, normally 20 to 60 days.

- Injection molding lead-time counted from sample approval and receipt of deposit to production finish, order quantity determines how much time is needed, normally 7 to 15 days.

5. Will TKB send DMF to customer?

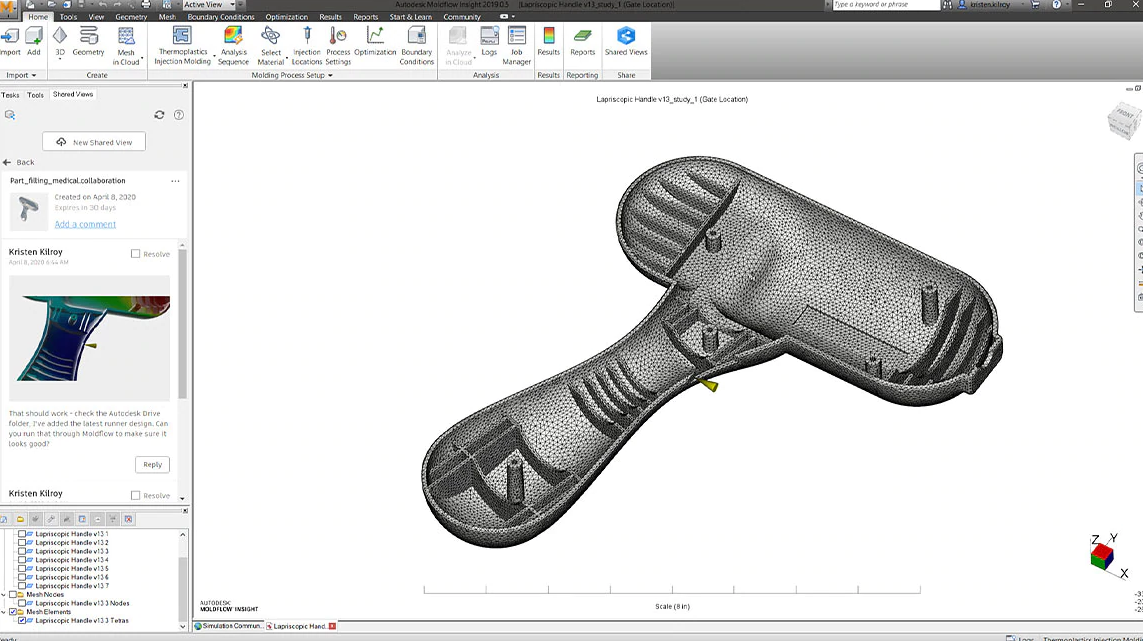

Yes,TKB Mold will send DFM (design for manufacturing) analysis and even mold flow analysis prior to the start of mold construction for customer review/approval.

6. Will TKB send mold design for approval?

After DMF approval, TKB will send the mould design for approval, and TKB will not start steel-cut before getting customers written approval of mold design.

7. How many plastic samples will be free provided?

TKB normally would provide 10~20 shots first mold trial shooting samples with gate(if have) free of charge according to the size of the parts, it would be freight to collect.

8. Which side provides plastic resin for injection mold trial?

TKB can provided plastic resin, if needed customer can provide the plastic resin the same.

9. How to make sure of quality before shipment?

shipment can be arranged only after TKB QC inspection PASS, or customer QC inspection PASS, or third-party inspection PASS if required. And TKB will always be there to provide full support.

10. How will TKB keep record of all mold data.

TKB will keep record of all final approved 2D, 3D mold drawing, modifications document, and send to customer for file to avoid future confusion in case engineering change is needed.