About molds for plastic toys

TKB Mold, being a professional injection mold supplier also provide injection molding service, adhere to sustainable development and technological innovation. Though TKB tooling cost is not the cheapest, TKB build quality mold that enable faster and more stable molding process, less material to waste, less labor requires, easier processing, and never compromised quality, and finally save more cost and create more value to customers and to the world!

Injection Mold for Plastic Toys

Plastic toys mold produced in China follow the local standards, the injection mold is required to made as cheap as possible as long as it produces the demanded quantity plastic parts. Usually plastic toys do not require high precision, so does the mold, family made mold is recommended.

Injection Molding for Plastic Toys

High volume injection molding production requires Class 101 molds, hot nozzle and automatic production design are recommended to minimize the molding cost, when you decide to add recycle plastic material, be careful about the density and strength it might affect. Toy parts always have colorful appearance, the color powder mix ratio and injection molding parameter must be fixed, otherwise, the color of each batch parts would have un-accepted deviation.

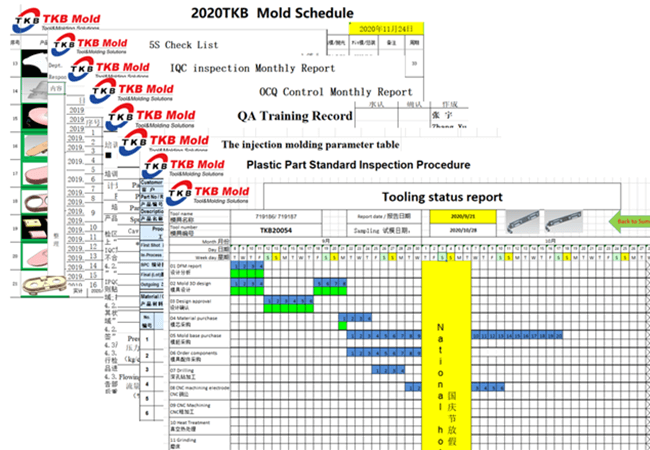

We are providing Custom Precision Mold Manufacturing Services. we make tooling according your demand of tooling specification (as what mold standard using? what size machine to be adapt your machine? what material and shrinkage using? what injection cycle time? mold life requirement? regarding these issues you can following our tooling specification sheet to be knew if you don’t understand about that). Normally, the manufacturing period from to 15 days to 60 days which it depend on the part size, mold structure complex or not, accuracy and mold life. We can make all the injection moulds that involving automobile, consumer electronic, office application, household application,industry and Commodity. Our team should keep you posted on progress as that you should receive that weekly process report, inspection report, injection parameter sheet and trail video, also you may check them at our service terms.

WHY CHOOSE TKB Injection Mold Manufacturing?

Your injection mold manufacturing makes your product from concept to reality?

Your injection mold is manufactured with the ideal precision?

Want custom plastic molds to without flashes and with durable mold die life?

Then start mold manufacturing at TKB Mold, and let’s creat an ideal injection mold solution for your product.

Out standing engineering team for export molds

Rich experience in mold fabrication

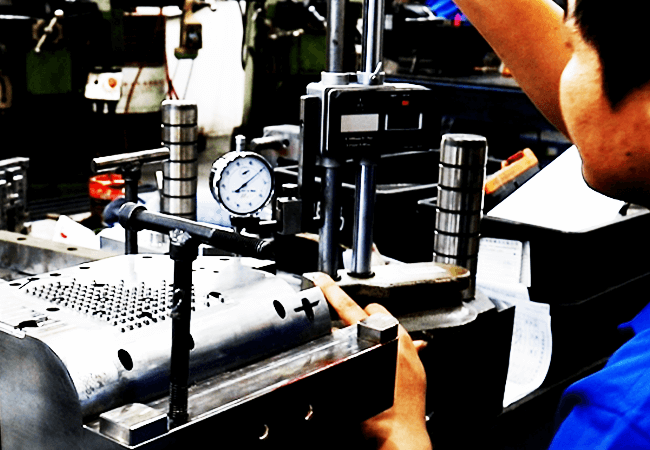

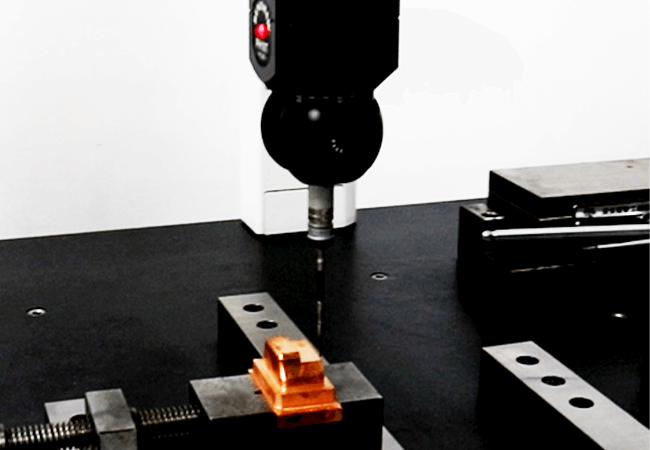

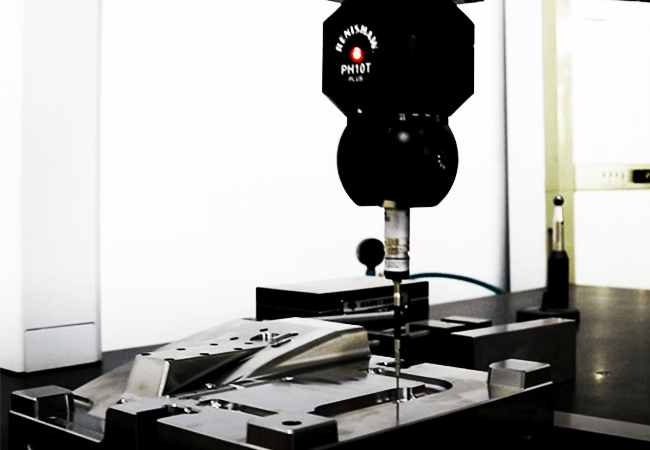

Advanced manufacturing equipment

Quality assurance of ISO9001: 2015 system

Fast delivery time

Excellent after sales service

TKB Process for Injection Mold Manufacturing

To make a good quality export plastic injection mold, processes as below for your reference:

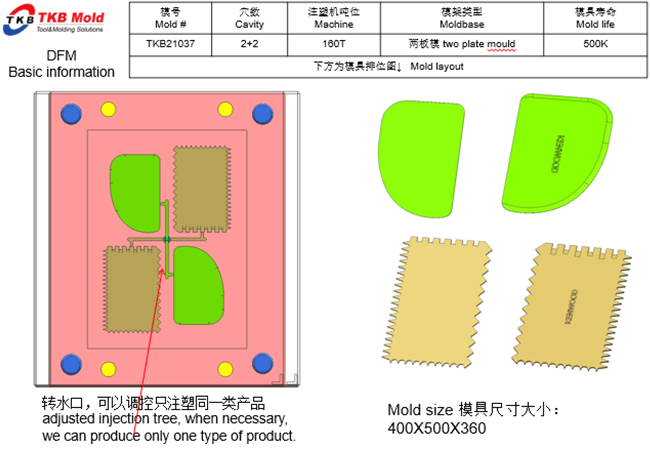

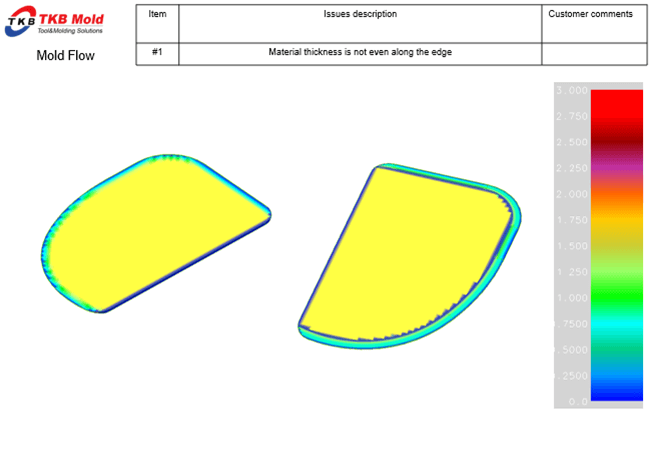

DFM Report, Mold Flow analysis, conclude 2D/3D Mold drawing, approval to mold fabrication.

Mold steel preparation—Processing—Mold Base Processing—-Electrodes Processing—-Mold Parts Processing—-Quality Control—–Mold Fitting and Assembly—Inspection—-Mold Trial—Mass Production Trial—Inspection PASS—Pack and export the Mold

TKB types of plastic injection mold

Since plastic injection mold is widely used for many industries, TKB mold has advantage for producing high precision injection molds as follows:

Automotive Mold +

Medical Mold +

Electronics Mold +

Home Appliance Mould +

Industrial Mold +

Aerospace Mold +

Overmold +

Precision Molds +