About large plastic mould maker

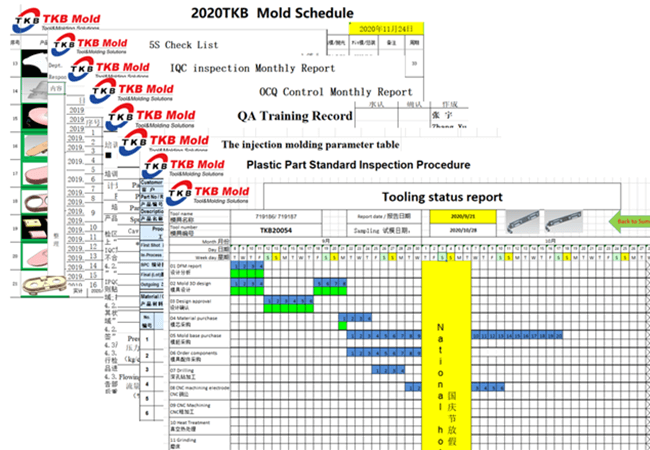

A large plastic mold maker is a company or business that specializes in designing and manufacturing plastic molds on a large scale. These molds are used to produce plastic products of various sizes and shapes, and can be customized to meet the specific needs of different clients.

Some common steps involved in the process of making plastic molds include:

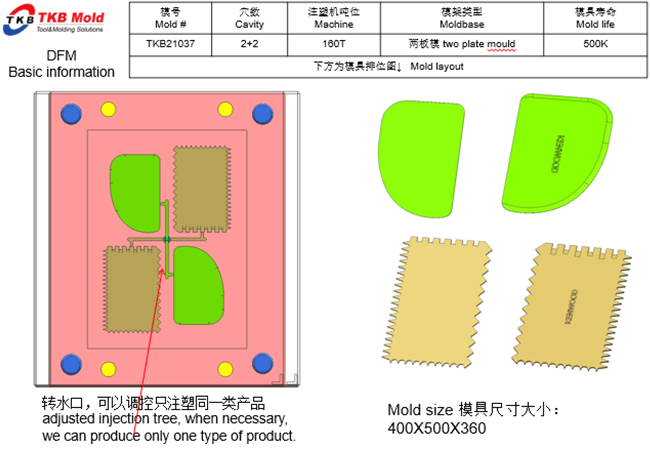

- Design: The first step in making a plastic mold is to design it using computer-aided design (CAD) software. The design should take into account the type of plastic material being used, the shape and size of the final product, and any other specific requirements of the client.

- Material selection: The type of plastic material used to make the mold will depend on the specific application and the requirements of the client. Common plastic materials used include polyethylene, polypropylene, polycarbonate, and ABS.

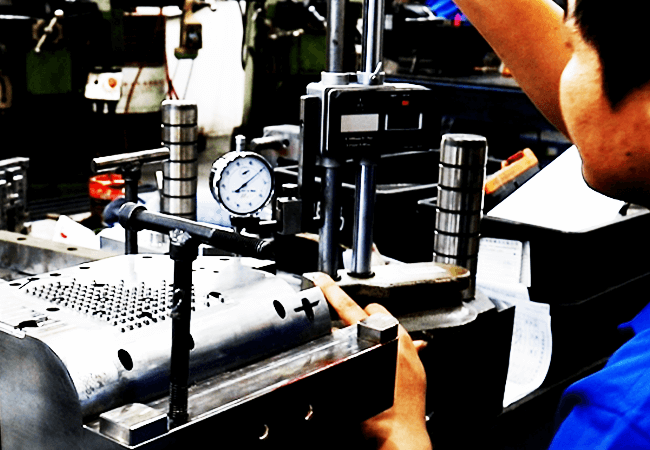

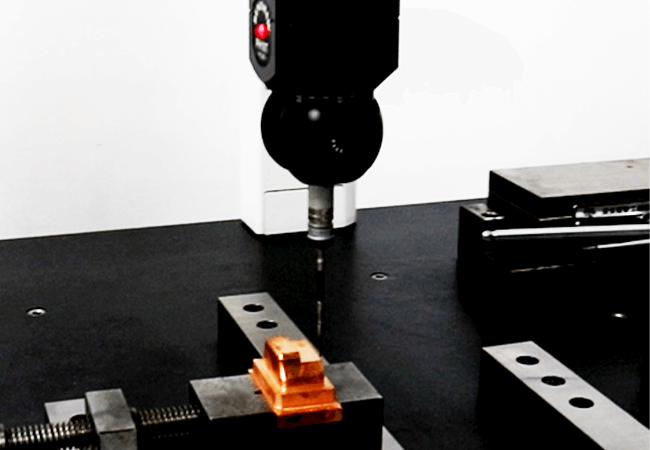

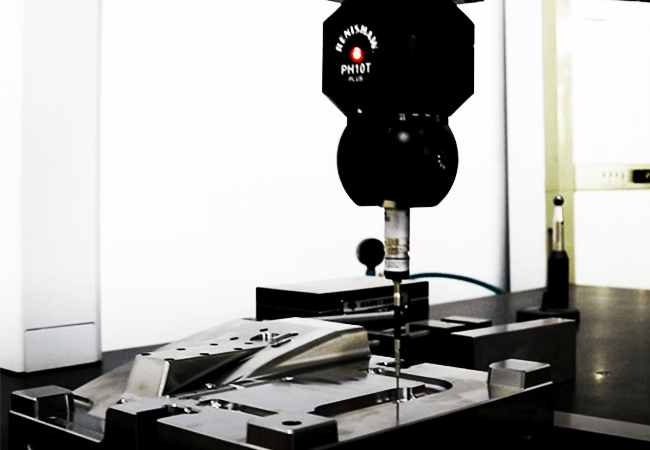

- Mold making: The mold is created by cutting the design into a block of steel or aluminum using CNC machines. The mold is then polished and finished to create a smooth surface.

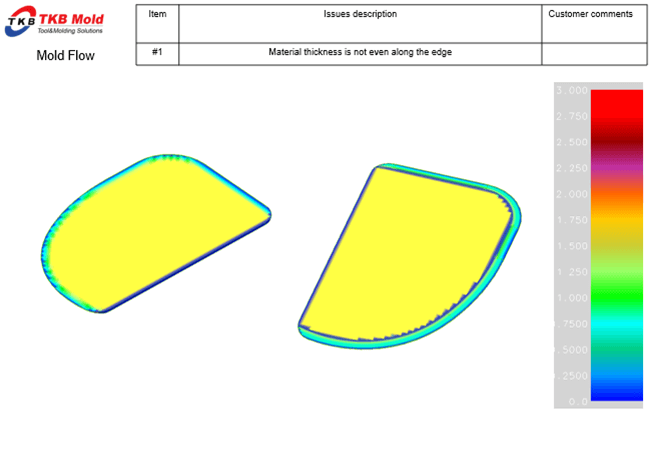

- Testing: Once the mold is completed, it is tested to ensure that it meets the client’s requirements. This may involve running test molds to produce sample plastic parts and checking for any defects or issues.

- Production: Once the mold has been approved, it can be used to produce large quantities of plastic parts.

Large plastic mold makers may also offer additional services such as mold maintenance, repair, and modification. It’s important to choose a reputable and experienced mold maker to ensure the highest quality and reliability of the finished product.