About A Look Inside TKB Mold China’s State-of-the-Art Manufacturing Facilities

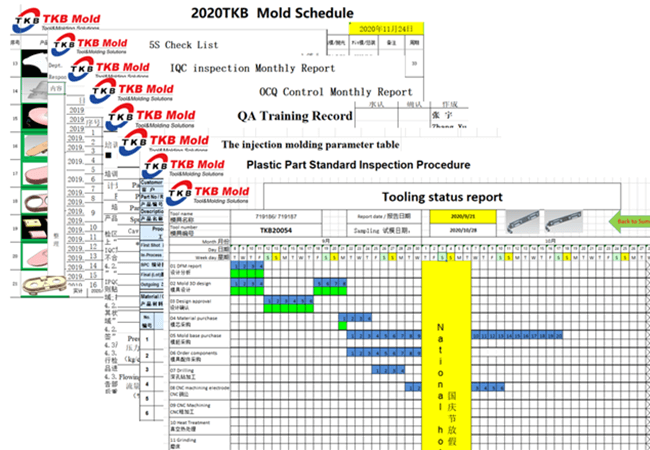

TKB Mold China operates from a state-of-the-art manufacturing Located in Dongguan, China. The facility is equipped with advanced technology and equipment to ensure that the company can provide high-quality molding solutions to clients from various industries.

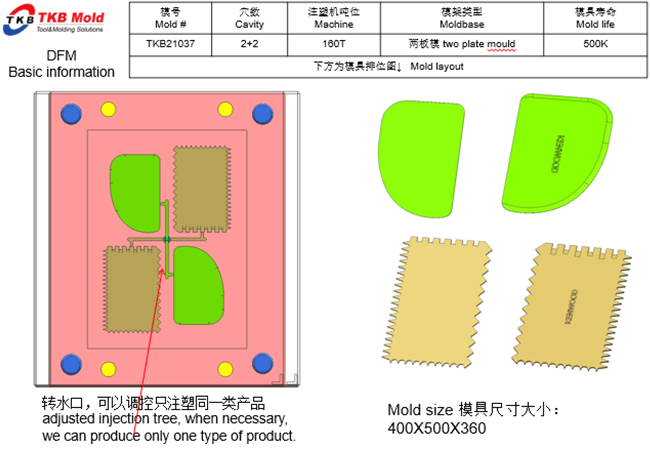

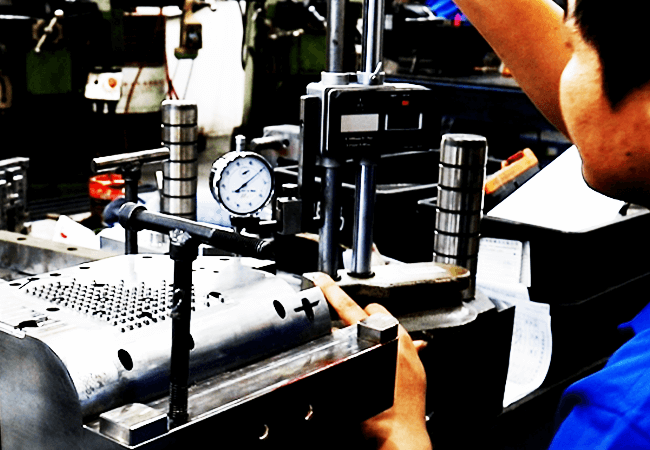

The manufacturing facility is divided into several sections, each dedicated to specific manufacturing processes. There are separate sections for plastic injection molding, die casting, blow molding, and precision machining. The facility also has a dedicated tool room where engineers and technicians design and produce molds to be used in the manufacturing process.

The plastic injection molding section is equipped with over 50 high-precision injection molding machines, ranging in capacity from 50 to 2000 tons. The machines are fully automated and equipped with advanced control systems to ensure that each product is of the highest quality.

The die casting section is equipped with a range of hot chamber and cold chamber die casting machines, ranging in capacity from 160 to 1200 tons. The machines are fully automated and equipped with advanced control systems to ensure that each product meets the required specifications.

The blow molding section is equipped with advanced blow molding machines capable of producing a range of products, including bottles, containers, and other hollow products. The machines are fully automated and equipped with advanced control systems to ensure that each product is of the highest quality.

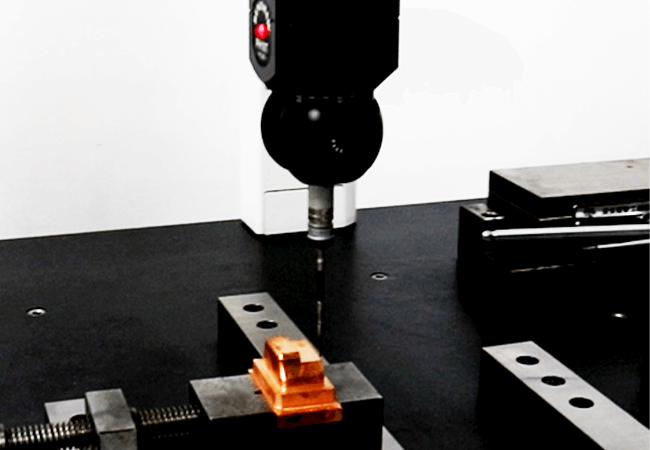

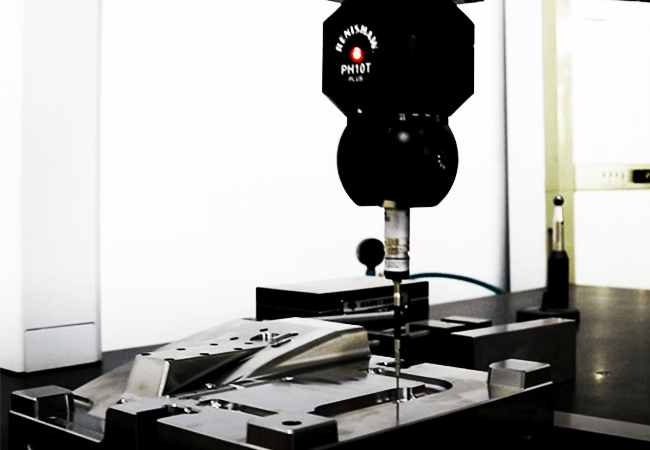

The precision machining section is equipped with advanced CNC machines capable of producing high-precision components with tolerances as low as 0.01mm. The machines are operated by skilled technicians who have years of experience in the field.

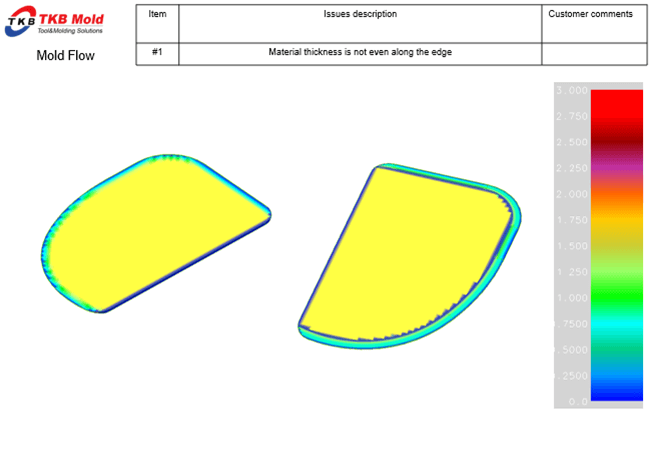

In addition to the manufacturing sections, the facility also has a dedicated quality control department that ensures that each product meets the required standards and specifications. The quality control department uses advanced testing equipment to perform a range of tests, including tensile testing, impact testing, and hardness testing.

Overall, TKB Mold China’s state-of-the-art manufacturing facilities are equipped with advanced technology and equipment to provide high-quality molding solutions to clients from various industries. The company’s commitment to quality and customer satisfaction is reflected in the quality of their products and services.