About Streamlining Production Processes with TPR Overmolding Mold in China

TPR (thermoplastic rubber) overmolding mold technology has revolutionized production processes in China’s manufacturing industry. By combining multiple manufacturing steps into one process, TPR overmolding molds have streamlined the production process and increased manufacturing efficiency. Here are some ways that TPR overmolding mold technology is streamlining production processes in China:

Reduced labor costs: TPR overmolding molds can reduce labor costs by automating multiple manufacturing steps. This reduces the need for manual labor, resulting in a more cost-effective manufacturing process.

Faster production times: TPR overmolding molds can significantly reduce production times by combining multiple manufacturing steps into one process. This can result in faster turnaround times and increased manufacturing efficiency.

Improved quality control: TPR overmolding mold technology allows for greater quality control by producing consistent, high-quality products. This reduces the need for inspections and rework, resulting in a more efficient manufacturing process.

Simplified supply chain: TPR overmolding molds can simplify the supply chain by producing a finished product in a single manufacturing step. This reduces the need for multiple suppliers and simplifies the logistics process.

Greater design flexibility: TPR overmolding mold technology provides greater design flexibility, allowing for the creation of complex shapes and designs. This enables manufacturers to create unique products that meet the customers’ requirements.

Reduced material waste: TPR overmolding mold technology can reduce material waste by producing products with less waste than traditional manufacturing methods. This reduces the need for raw materials and saves on manufacturing costs.

Overall, TPR overmolding mold technology has streamlined production processes in China’s manufacturing industry. By reducing labor costs, improving production times, and simplifying the supply chain, TPR overmolding molds have made the manufacturing process more efficient and cost-effective.

MIÉRT VÁLASSZON TKB fröccsöntő forma gyártás?

Az Ön fröccsöntő gyártása az ötlettől a valósággá teszi termékét?

Az Ön fröccsöntő formája ideális precizitással készül?

Egyedi műanyag öntőformákat szeretne villogás nélkül és tartós formakivágással?

Then start mold manufacturing at TKB Mold, and let’s creat an ideal injection mold solution for your product.

Kiváló mérnöki csapat az exportformákhoz

Gazdag tapasztalat a formagyártásban

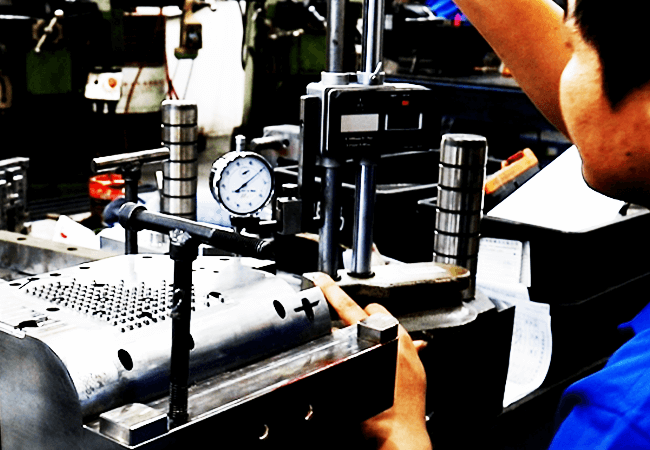

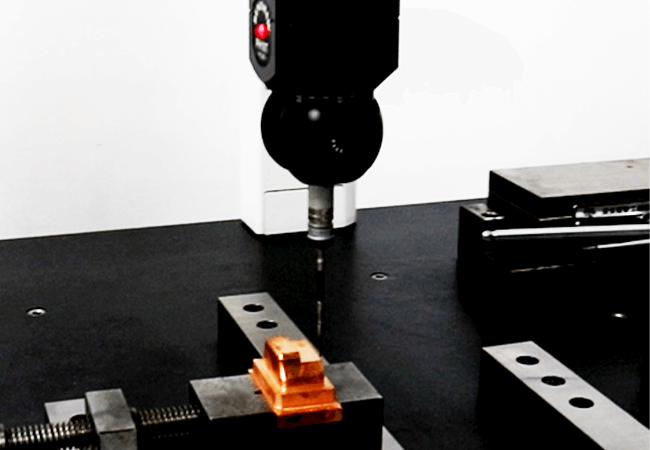

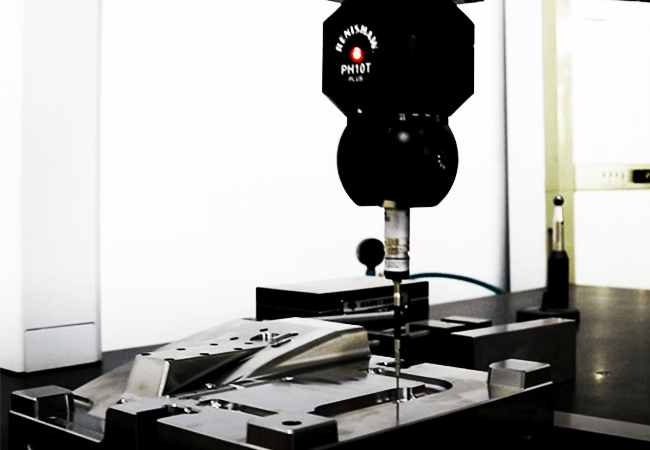

Fejlett gyártóberendezések

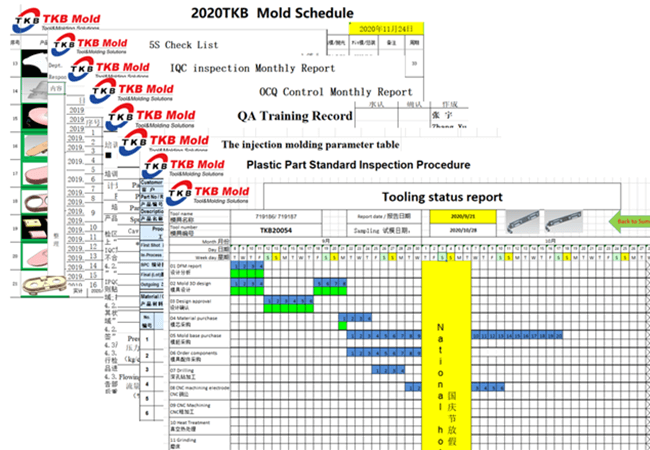

Az ISO9001: 2015 rendszer minőségbiztosítása

Gyors szállítási idő

Kiváló értékesítés utáni szolgáltatás

TKB folyamat a fröccsöntő formagyártáshoz

Jó minőségű export műanyag fröccsöntő öntőforma készítéséhez kövesse az alábbi eljárásokat referenciaként:

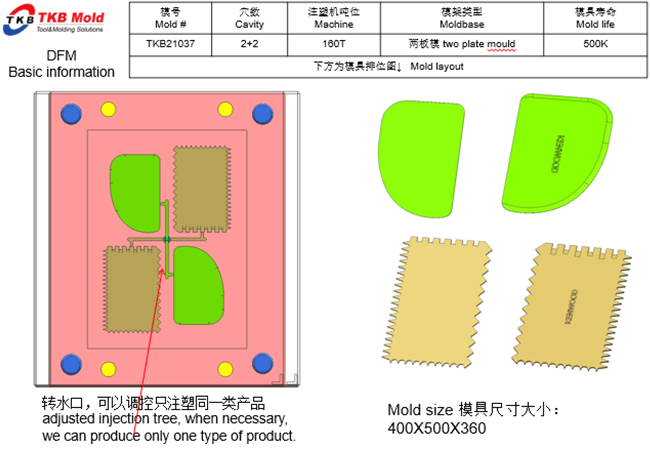

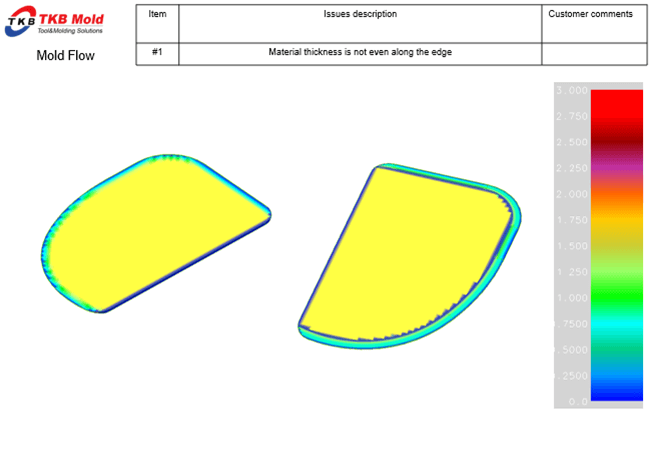

DFM jelentés, formaáramlás elemzés, 2D/3D formarajz megkötése, öntőforma gyártásának jóváhagyása.

Mold steel preparation—Processing—Mold Base Processing—-Electrodes Processing—-Mold Parts Processing—-Quality Control—–Mold Fitting and Assembly—Inspection—-Mold Trial—Mass Production Trial—Inspection PASS—Pack and export the Mold

TKB típusok műanyag fröccsöntő forma

Mivel a műanyag fröccsöntő formát széles körben használják számos iparágban, a TKB öntőforma előnye a nagy pontosságú fröccsöntő szerszámok előállításához az alábbiak szerint:

Automotive Mold +

Medical Mold +

Electronics Mold +

Háztartási gép penész +

Industrial Mold +

Aerospace Mold +

Overmold +

Precision Molds +