About injection mold supplies

Injection mold supplies are a necessary part of the injection molding process. Injection molding is a manufacturing process for producing parts by injecting molten material into a mold. The material is usually a plastic, but can also be metal. The mold is a hollowed out block of metal, ceramic, or other material. The molten material is injected into the mold through a small hole, called a sprue. The material then fills the mold, and is allowed to cool and solidify. After the material has cooled, the mold is opened, and the part is removed. Injection molding is used to produce a wide variety of parts, including medical devices, car parts, and consumer goods. Injection molding is a complex process.

Injection molding is a manufacturing process for producing parts by injecting molten material into a mold. The material is usually a plastic, but can also be metal.

The process begins by heating the material to a molten state. The molten material is then injected into a mold, where it is allowed to cool and solidify. After the material has cooled, the mold is opened, and the part is removed.

Injection molding is used to produce a wide variety of parts, including medical devices, car parts, and consumer goods. Injection molding is a complex process, and there are many factors that can influence the quality of the final product.

Some of the factors that can affect the quality of the part include the type of material, the size and shape of the part, the speed of the injection process, and the temperature of the material.

In order to produce a high-quality part, it is important to optimize each of these factors.

MIÉRT VÁLASSZON TKB fröccsöntő forma gyártás?

Az Ön fröccsöntő gyártása az ötlettől a valósággá teszi termékét?

Az Ön fröccsöntő formája ideális precizitással készül?

Egyedi műanyag öntőformákat szeretne villogás nélkül és tartós formakivágással?

Then start mold manufacturing at TKB Mold, and let’s creat an ideal injection mold solution for your product.

Kiváló mérnöki csapat az exportformákhoz

Gazdag tapasztalat a formagyártásban

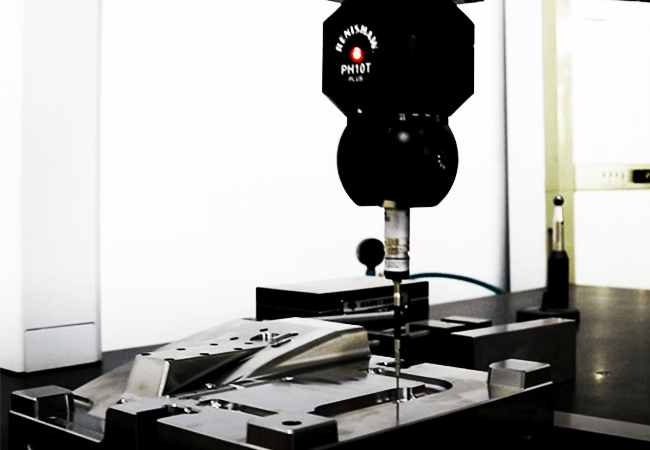

Fejlett gyártóberendezések

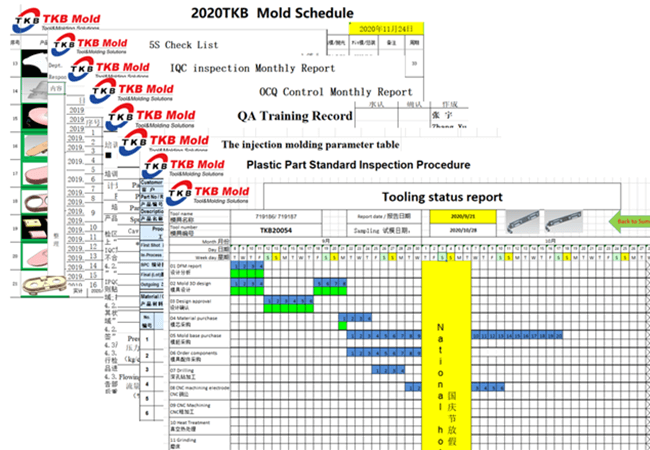

Az ISO9001: 2015 rendszer minőségbiztosítása

Gyors szállítási idő

Kiváló értékesítés utáni szolgáltatás

TKB folyamat a fröccsöntő formagyártáshoz

Jó minőségű export műanyag fröccsöntő öntőforma készítéséhez kövesse az alábbi eljárásokat referenciaként:

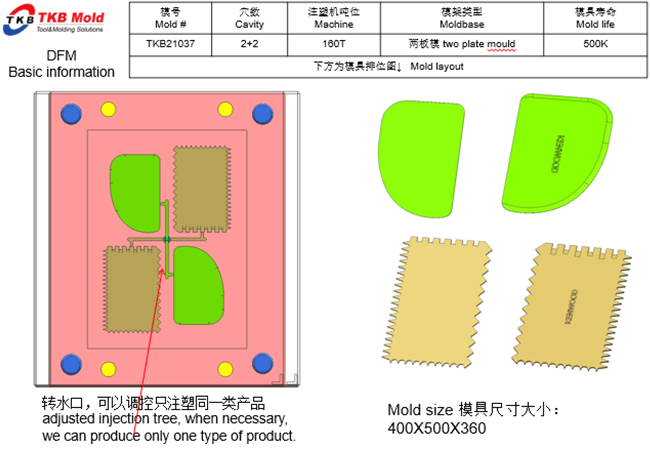

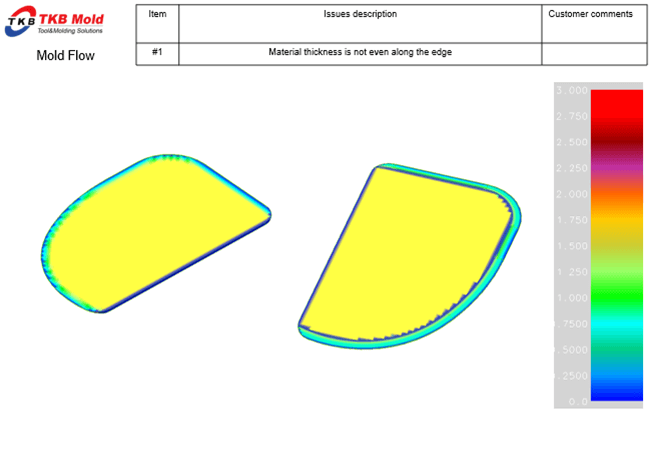

DFM jelentés, formaáramlás elemzés, 2D/3D formarajz megkötése, öntőforma gyártásának jóváhagyása.

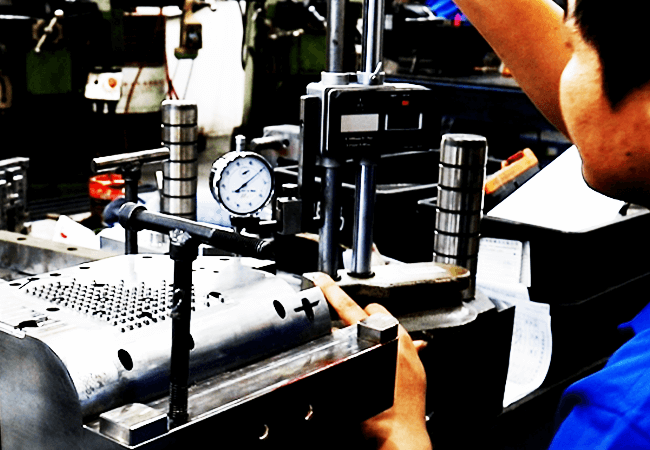

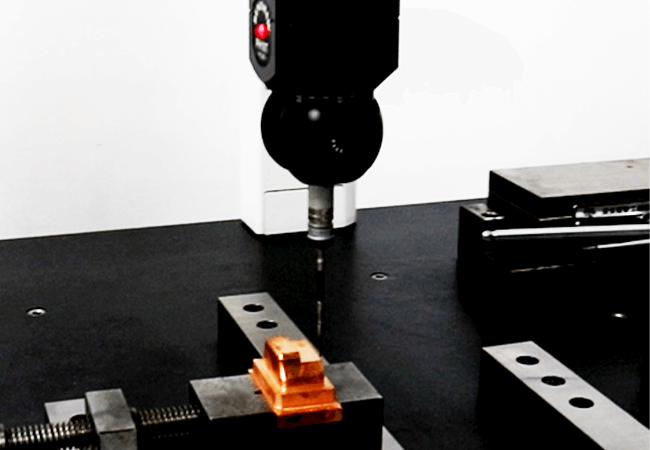

Mold steel preparation—Processing—Mold Base Processing—-Electrodes Processing—-Mold Parts Processing—-Quality Control—–Mold Fitting and Assembly—Inspection—-Mold Trial—Mass Production Trial—Inspection PASS—Pack and export the Mold

TKB típusok műanyag fröccsöntő forma

Mivel a műanyag fröccsöntő formát széles körben használják számos iparágban, a TKB öntőforma előnye a nagy pontosságú fröccsöntő szerszámok előállításához az alábbiak szerint:

Automotive Mold +

Medical Mold +

Electronics Mold +

Háztartási gép penész +

Industrial Mold +

Aerospace Mold +

Overmold +

Precision Molds +