About custom plastic injection molders

We have two injection molding service options – prototyping and on-demand manufacturing – each offering its own advantages based on your project needs. If part quantities are high, affordable part prices are important, and rapid production throughout the product life cycle is critical. For this, our on-demand manufacturing option is ideal.

How does plastic injection molding work?

A hőre lágyuló fröccsöntési eljárás egy szabványos eljárás, amely alumínium öntőformákat használ. Az alumínium hatékonyabban adja át a hőt, mint az acél, így nincs szükség hűtőcsatornákra – vagyis az általunk megtakarított hűtési idő felhasználható a töltési nyomás, a kozmetikai problémák és a termékek ellenőrzésére.

What can injection molding be used for?

Injection molding is used to manufacture a variety of widely used products. If you look around your desk/home, you’ll find a plethora of injection molded products, including bottle caps, remote control housings, console covers, syringes, and most plastics.

What does an injection molding machine do?

Injection molding is a manufacturing process that allows parts to be produced in large quantities. It works by injecting molten material into a mold. It is often used as a mass production process to make thousands of identical items.

MIÉRT VÁLASSZON TKB fröccsöntő forma gyártás?

Az Ön fröccsöntő gyártása az ötlettől a valósággá teszi termékét?

Az Ön fröccsöntő formája ideális precizitással készül?

Egyedi műanyag öntőformákat szeretne villogás nélkül és tartós formakivágással?

Then start mold manufacturing at TKB Mold, and let’s creat an ideal injection mold solution for your product.

Kiváló mérnöki csapat az exportformákhoz

Gazdag tapasztalat a formagyártásban

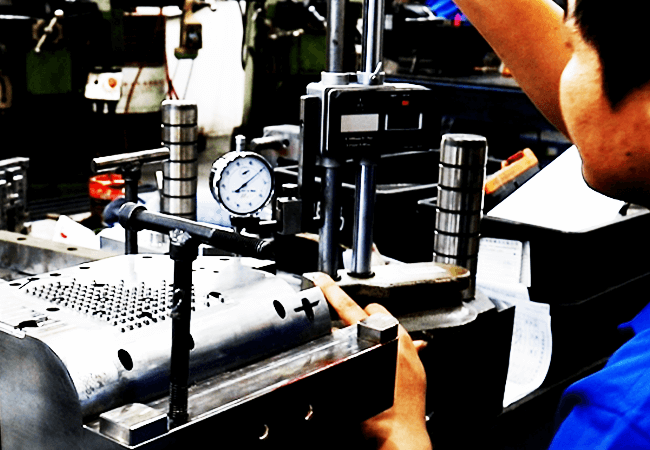

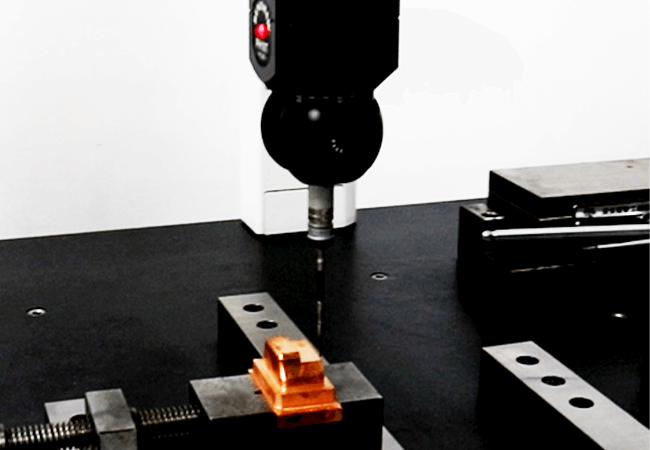

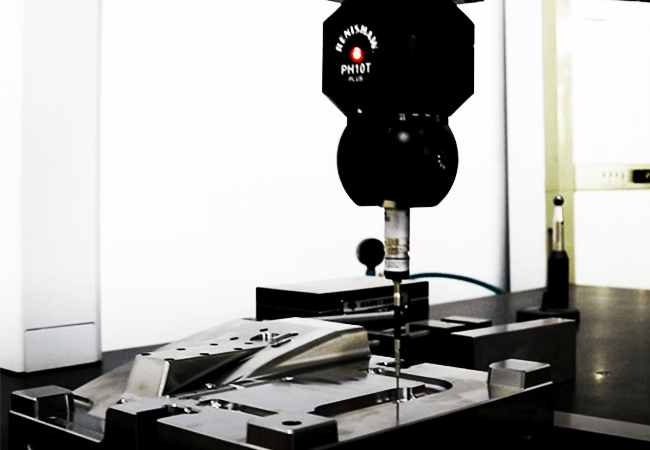

Fejlett gyártóberendezések

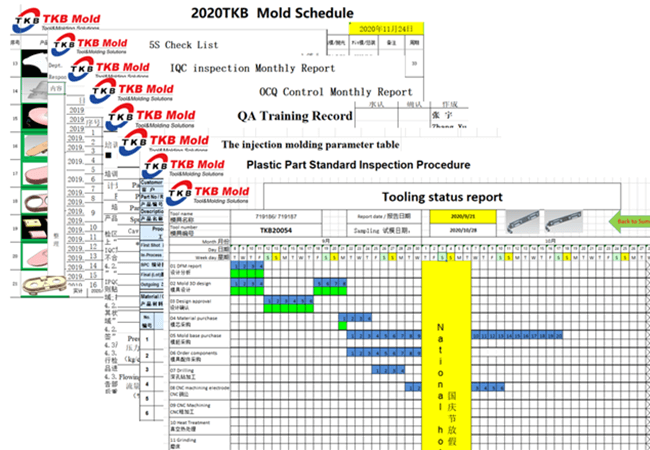

Az ISO9001: 2015 rendszer minőségbiztosítása

Gyors szállítási idő

Kiváló értékesítés utáni szolgáltatás

TKB folyamat a fröccsöntő formagyártáshoz

Jó minőségű export műanyag fröccsöntő öntőforma készítéséhez kövesse az alábbi eljárásokat referenciaként:

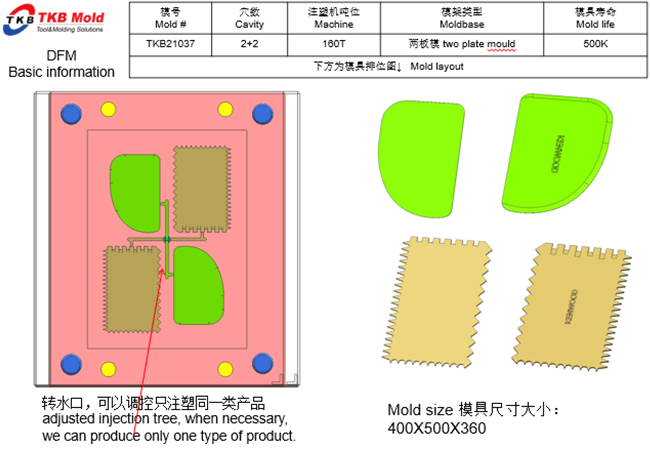

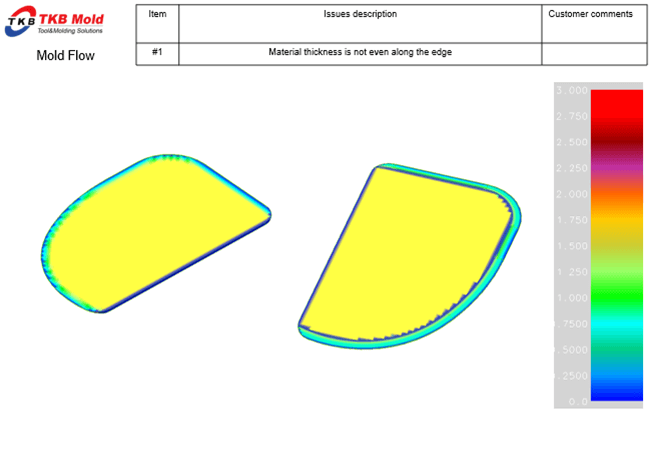

DFM jelentés, formaáramlás elemzés, 2D/3D formarajz megkötése, öntőforma gyártásának jóváhagyása.

Mold steel preparation—Processing—Mold Base Processing—-Electrodes Processing—-Mold Parts Processing—-Quality Control—–Mold Fitting and Assembly—Inspection—-Mold Trial—Mass Production Trial—Inspection PASS—Pack and export the Mold

TKB típusok műanyag fröccsöntő forma

Mivel a műanyag fröccsöntő formát széles körben használják számos iparágban, a TKB öntőforma előnye a nagy pontosságú fröccsöntő szerszámok előállításához az alábbiak szerint:

Automotive Mold +

Medical Mold +

Electronics Mold +

Háztartási gép penész +

Industrial Mold +

Aerospace Mold +

Overmold +

Precision Molds +