About Quality Mold Case Study

Quality Mold in Action: A Case Study of Improved Product Quality

In today’s competitive manufacturing landscape, ensuring that your products meet the highest standards of quality is essential to your success. That’s why more and more companies are turning to quality mold practices to achieve the level of precision and consistency needed to stay ahead of the competition. In this case study, we’ll take a closer look at how one manufacturer implemented quality mold practices to improve product quality and stay ahead of the curve.

The Challenge

A leading manufacturer of automotive components was facing increasing pressure to meet the ever-growing demands of their customers for high-quality products. However, they were struggling to achieve the level of precision and consistency required to meet these demands. They were experiencing high rates of scrap and rejections, which were impacting their bottom line and damaging their reputation in the market.

The Solution

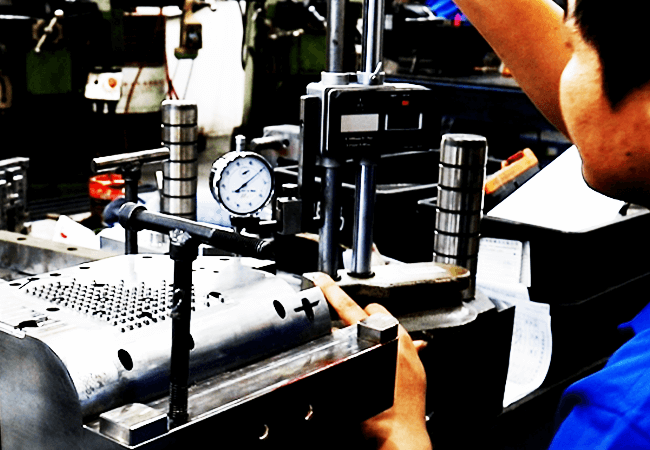

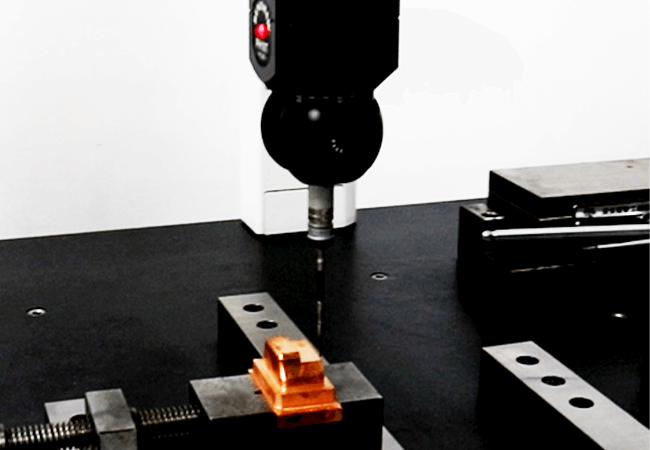

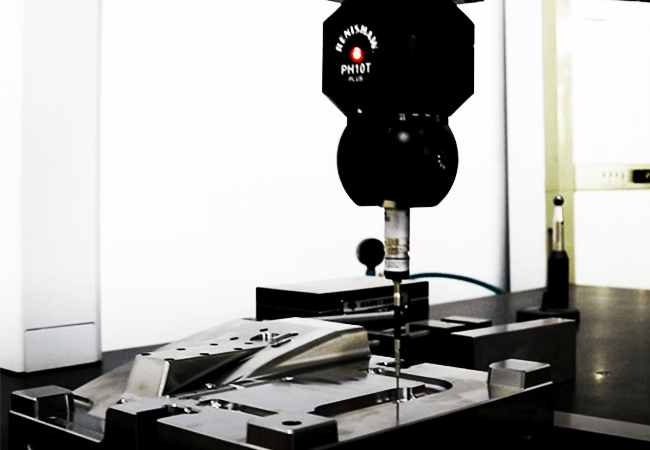

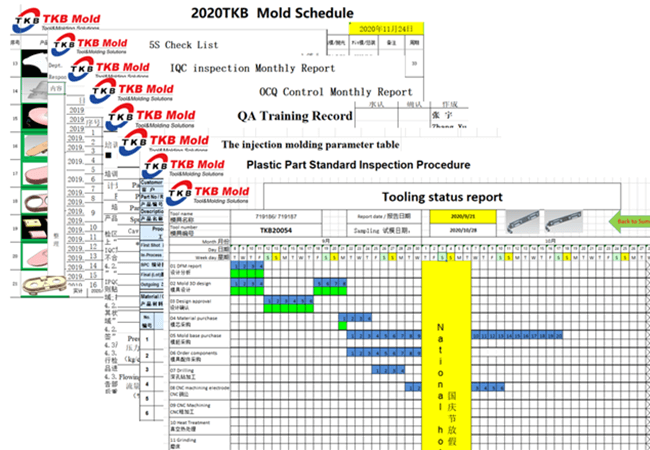

To address these challenges, the manufacturer decided to implement quality mold practices throughout their production process. This included investing in advanced equipment and technology to improve the accuracy and consistency of their molds, as well as implementing strict quality control procedures to ensure that each part met the highest standards of quality.

The Results

The results of these efforts were impressive. The manufacturer was able to reduce their scrap and rejections rates by over 50%, resulting in significant cost savings and improved productivity. They also saw an increase in customer satisfaction, as their products were consistently meeting the high standards of quality that their customers had come to expect.

Conclusion

This case study demonstrates the importance of quality mold practices in achieving the highest levels of product quality and customer satisfaction. By investing in advanced equipment and technology and implementing strict quality control procedures, manufacturers can improve their competitiveness in the market and stay ahead of the curve. So if you’re looking to take your manufacturing to the next level, consider implementing quality mold practices throughout your production process.

WHY CHOOSE TKB Injection Mold Manufacturing?

Your injection mold manufacturing makes your product from concept to reality?

Your injection mold is manufactured with the ideal precision?

Want custom plastic molds to without flashes and with durable mold die life?

Then start mold manufacturing at TKB Mold, and let’s creat an ideal injection mold solution for your product.

Out standing engineering team for export molds

Rich experience in mold fabrication

Advanced manufacturing equipment

Quality assurance of ISO9001: 2015 system

Fast delivery time

Excellent after sales service

TKB Process for Injection Mold Manufacturing

To make a good quality export plastic injection mold, processes as below for your reference:

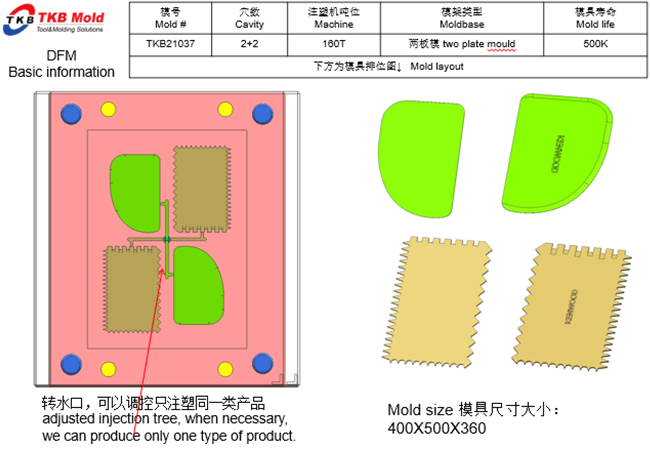

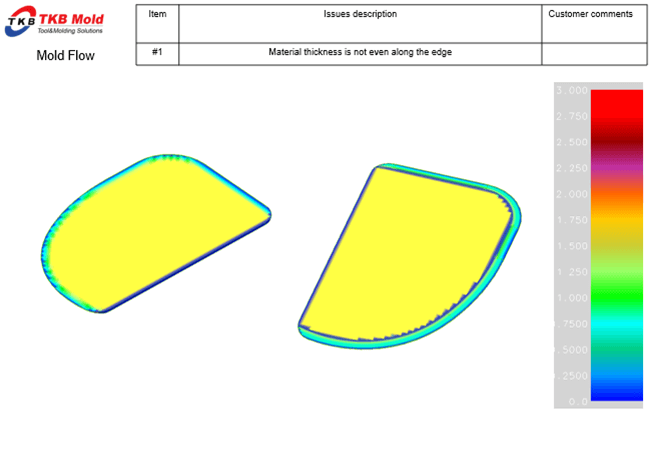

DFM Report, Mold Flow analysis, conclude 2D/3D Mold drawing, approval to mold fabrication.

Mold steel preparation—Processing—Mold Base Processing—-Electrodes Processing—-Mold Parts Processing—-Quality Control—–Mold Fitting and Assembly—Inspection—-Mold Trial—Mass Production Trial—Inspection PASS—Pack and export the Mold

TKB types of plastic injection mold

Since plastic injection mold is widely used for many industries, TKB mold has advantage for producing high precision injection molds as follows:

Automotive Mold +

Medical Mold +

Electronics Mold +

Home Appliance Mould +

Industrial Mold +

Aerospace Mold +

Overmold +

Precision Molds +