About plastic injection molding parts

When it comes to plastic injection molding, it’s important to select the best parts for your needs. There are a variety of factors to consider, including the type of plastic, the dimensions of the part, and the required tolerances. With so many options available, it can be difficult to know where to start.

The benefits of using plastic injection molding parts.

There are many benefits to using plastic injection molding parts. Some of the benefits include:

1. Increased production rates – Injection molding can produce parts much faster than traditional methods such as casting or machining.

2. Reduced costs – Injection molding is a very cost effective way to produce parts in large quantities.

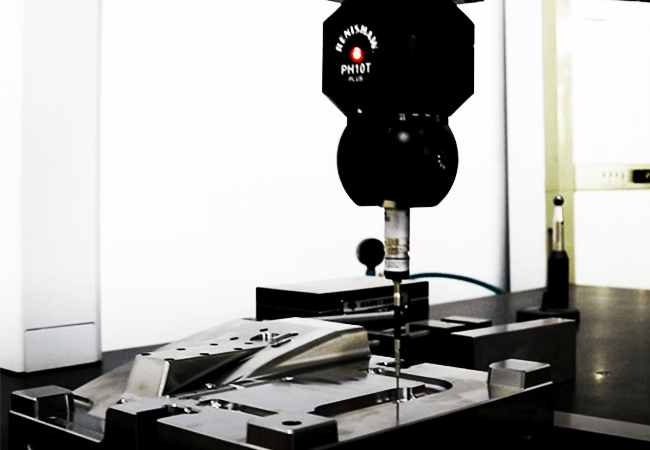

3. Increased accuracy – Injection molding produces parts with a very high degree of accuracy.

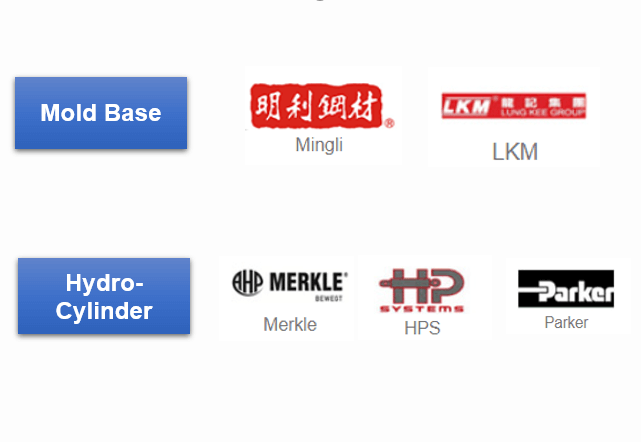

4. Variety of materials – Injection molding can use a wide variety of materials, including both thermoplastic and thermoset polymers.

5. Low waste – Injection molding produces very little waste compared to other manufacturing methods.

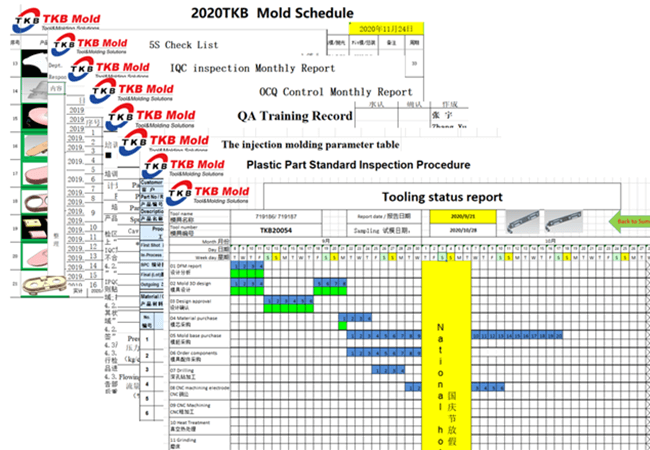

6. Shorter lead times – Injection molding typically has shorter lead times than other manufacturing methods.

7. Flexibility – Injection molding can be used to produce a wide variety of parts, including both small and large parts.

8. Ease of use – Injection molding is a relatively easy process to learn and use.

9. Low cost of ownership – Injection molding has a low cost of ownership compared to other manufacturing methods.

10. Customizable – Injection molding can be customized to meet the specific needs of a customer.

How to find the best plastic injection molding parts for your needs.

When it comes to finding plastic injection molding parts, it is important to know what you are looking for. Not all parts are created equal, and some will be a better fit for your needs than others.