About plastic chair mould

A plastic chair mould is a device used to create the shape of a plastic chair. It is made out of two halves that are joined together to form the shape of the chair. The plastic is then injected into the mould and allowed to harden.The two halves are then separated and the chair is removed.This technique is also used on other types of chairs, such as those with spindles in the back.The following technique can also be used to make the seat of a chair more comfortable.

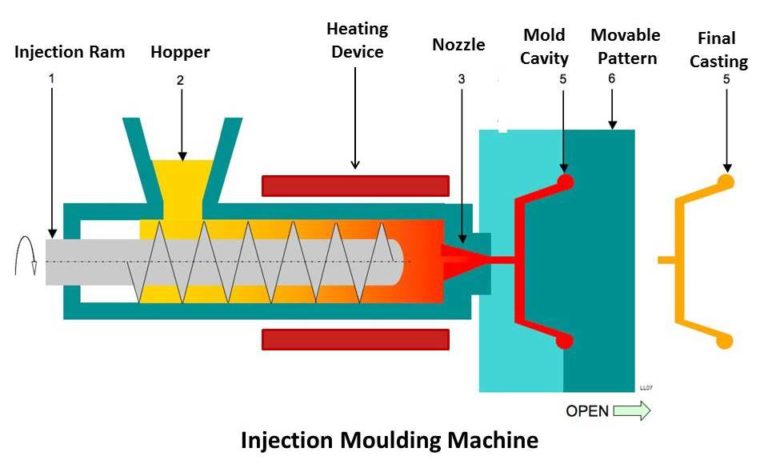

Injection moulding is a manufacturing process used to create objects from plastic materials. Injection moulding involves the use of a mould to create a shape out of molten plastic. The molten plastic is then injected into the mould, where it hardens to form the desired object. Injection moulding can be used to create a wide variety of objects, including chairs, bottles, and medical devices.

There are a number of different factors that need to be considered when designing an object for injection moulding. The size and shape of the object, the type of plastic material to be used, and the number of objects to be produced all need to be considered. The object must also be designed with manufacturing in mind. That means that the object must be able to be manufactured using the injection moulding process.

The injection moulding process begins by heating the plastic material to a molten state. The molten plastic is then injected into the mould, where it hardens to form the desired object. The mould is then cooled and opened, and the object is ejected.