About Large plastic mold manufacturer

A plastic mold is a tool that is matched with plastic molding machines in the plastics processing industry to give plastic products a complete configuration and precise size. Due to the variety of plastic varieties and processing methods, and the complex and simple structures of plastic molding machines and plastic products, the types and structures of plastic molds are also diverse.

A plastic mold is a tool for producing plastic products. It consists of several groups of parts, and this combination has a molding cavity. During injection molding, the mold is clamped on the injection molding machine, the molten plastic is injected into the molding cavity, and cooled and shaped in the cavity, and then the upper and lower molds are separated, and the product is ejected from the cavity through the ejection system to leave the mold, and finally, the mold is closed again. For the next injection, the entire injection process is cyclic.

Generally, a plastic mold consists of a movable mold and a fixed mold. The movable mold is installed on the moving template of the injection molding machine, and the fixed mold is installed on the fixed template of the injection molding machine. During injection molding, the movable mold and the fixed mold are closed to form a gating system and a cavity. When the mold is opened, the movable mold and the fixed mold are separated to take out the plastic product.

WAAROM ZOU JE KIEZEN TKB Spuitgietmatrijzenbouw?

Uw spuitgietproductie maakt uw product van concept tot realiteit?

Uw spuitgietmatrijs met de ideale precisie vervaardigd?

Wilt u op maat gemaakte plastic mallen zonder flitsen en met een duurzame levensduur van de matrijs?

Then start mold manufacturing at TKB Mold, and let’s creat an ideal injection mold solution for your product.

Uitstekend technisch team voor exportmatrijzen

Rijke ervaring in vormvervaardiging

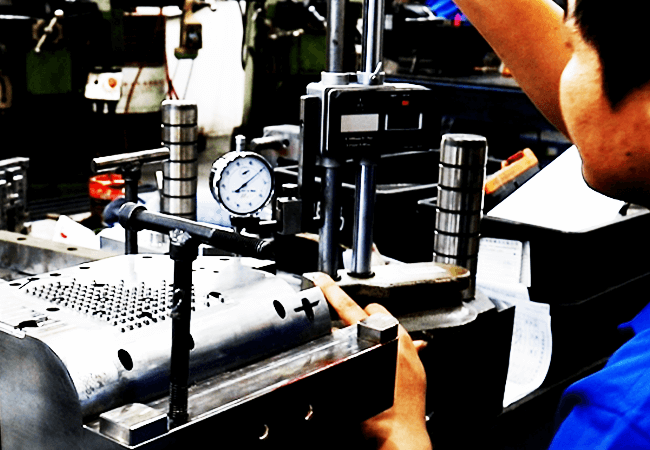

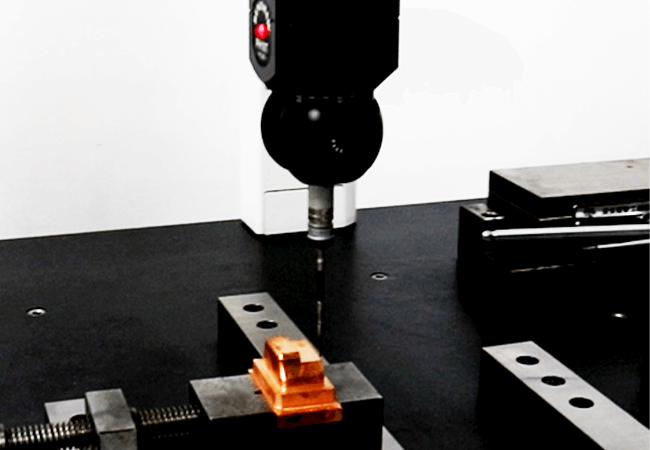

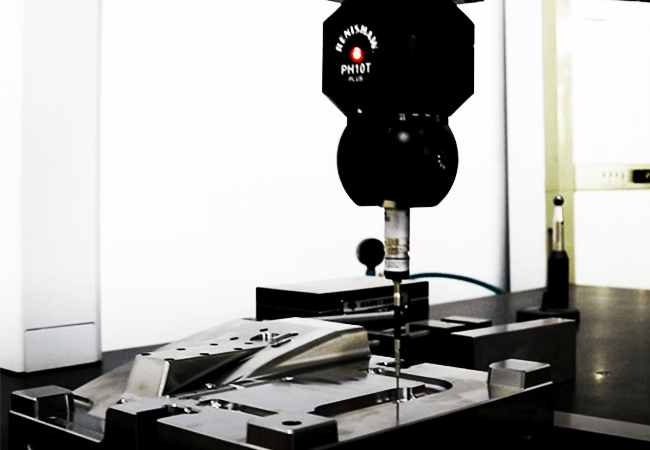

Geavanceerde productieapparatuur

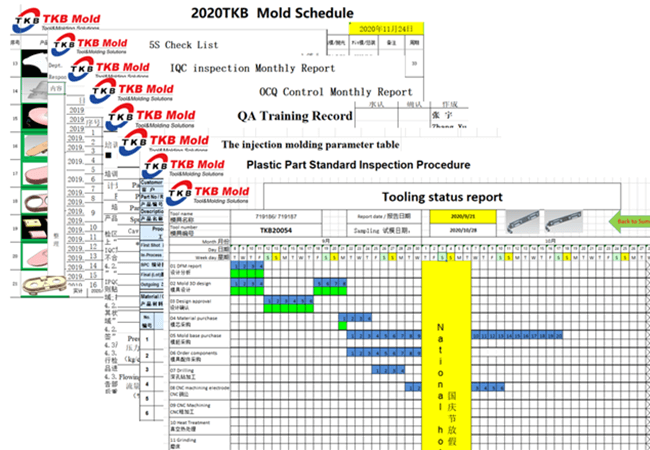

Kwaliteitsborging van ISO9001: 2015-systeem

Snelle levertijd

Uitstekende service na verkoop

TKB-proces voor de productie van spuitgietmatrijzen

Om een export plastic spuitgietmatrijs van goede kwaliteit te maken, processen zoals hieronder voor uw referentie:

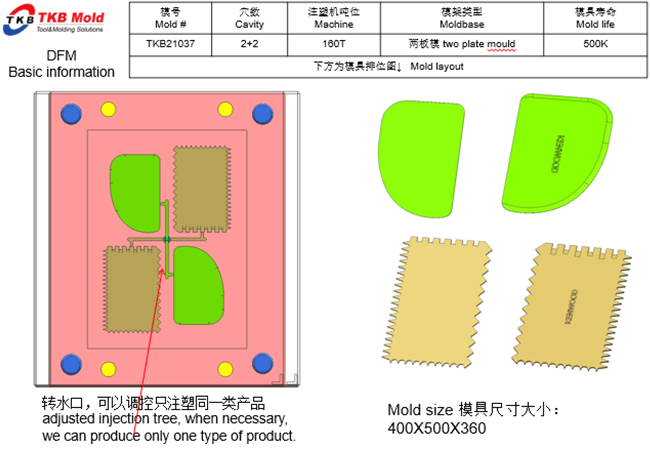

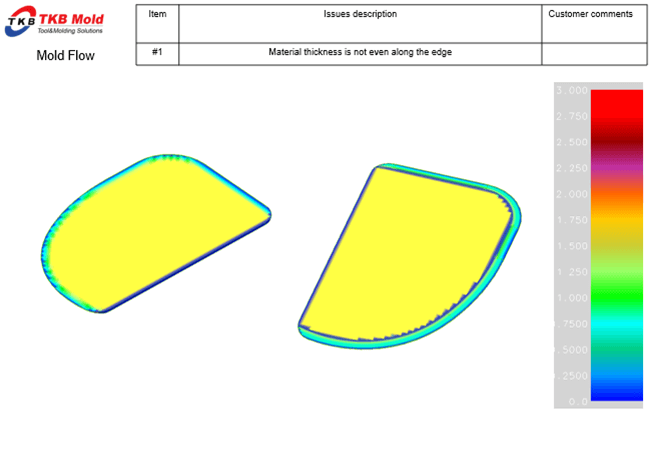

DFM-rapport, Mold Flow-analyse, conclusie 2D / 3D Mold-tekening, goedkeuring voor matrijsfabricage.

Mold steel preparation—Processing—Mold Base Processing—-Electrodes Processing—-Mold Parts Processing—-Quality Control—–Mold Fitting and Assembly—Inspection—-Mold Trial—Mass Production Trial—Inspection PASS—Pack and export the Mold

TKB-typen van kunststof spuitgietmatrijs

Aangezien kunststof spuitgietmatrijzen op grote schaal worden gebruikt voor veel industrieën, heeft TKB-vorm het voordeel om als volgt zeer nauwkeurige spuitgietmatrijzen te produceren:

Automotive Mold +

Medical Mold +

Electronics Mold +

Schimmel voor huishoudelijke apparaten +

Industrial Mold +

Aerospace Mold +

Overschimmel +

Precision Molds +