About How to choose the right plastic injection mold

In recent years, the mold industry has been in high demand, and its trend is retouching. The term mold is a hollowed out block or rigid frame. When filled with liquids or malleable materials such as plastic, glass, ceramic materials, etc., it reinforces the material or adds value-added functional properties. When the liquid hardens after cooling, it solidifies inside the mold and takes the desired shape. By adopting this valuable technology, insert molding manufacturers are now able to meet the diverse needs of their customers.

Based on this concept, insert molding suppliers also offer the most requested products in customized form. Now, insert molding has proven to be an effective alternative to assembling isolation components using welding, connectors, fasteners or adhesives.

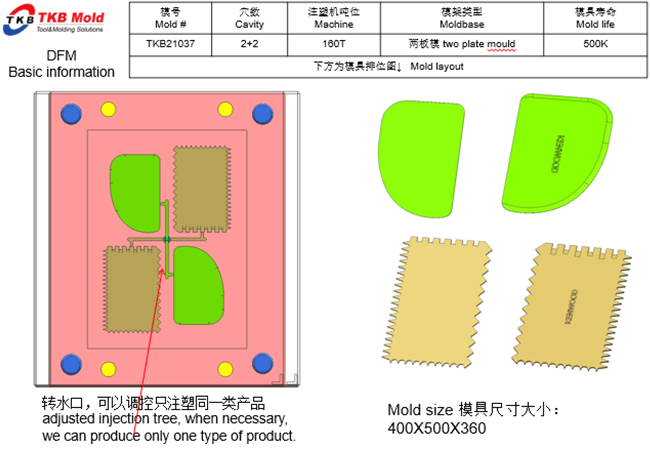

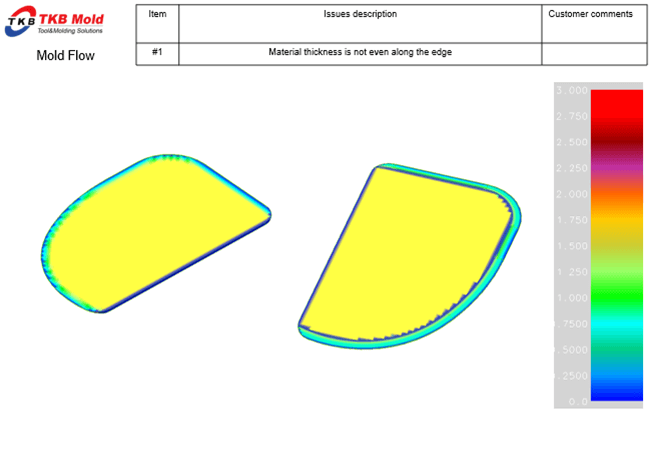

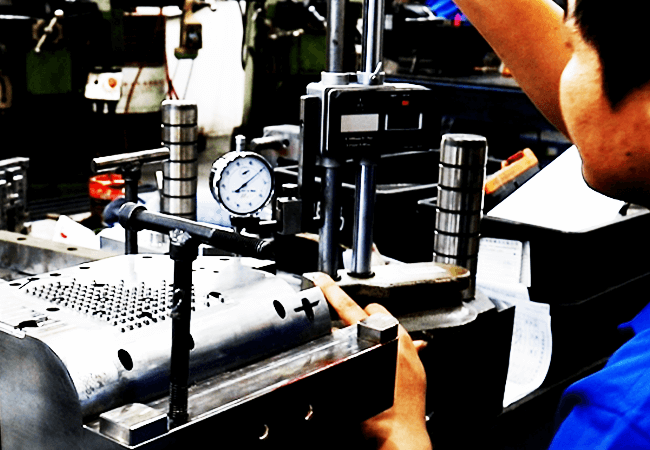

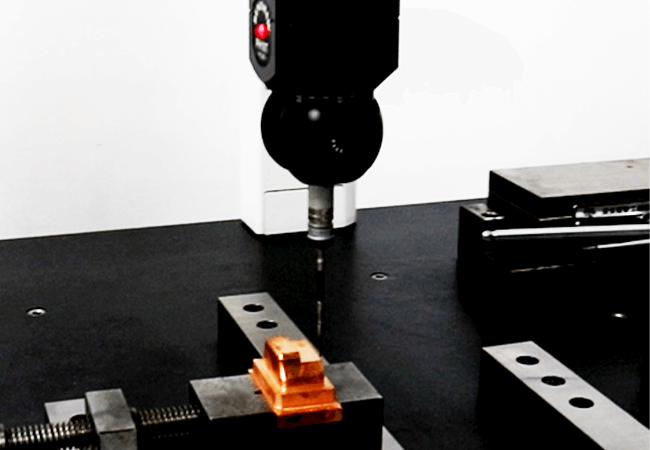

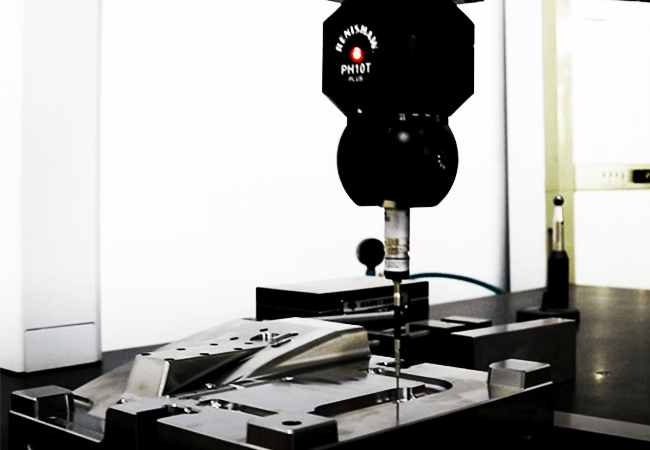

Insert molding is a high-tech process in which a pre-formed or machined part is inserted into a cavity while the mold is opened, and the material is then injected correctly. The main benefits of an insert molding supplier to a quality insert mold are-

• Insert molding thermoplastics connect so many components, greatly reducing assembly and labor costs.

• It provides smaller, lighter products by eliminating fasteners and connectors and by increasing the physical strength of resin and metal inserts.

• Insert-molded components prevent loose parts, misalignment, improper termination and other problems. Thermoplastic resins also offer better shock and vibration resistance, which provides greater reliability.

• It provides greater design flexibility.

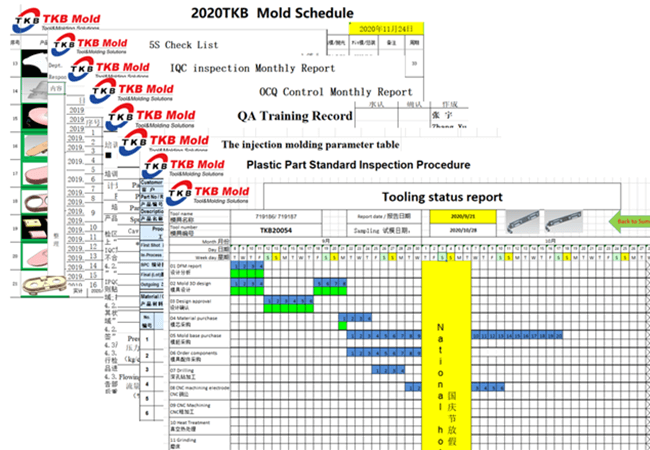

Choose the right plastic mold supplier

The importance of plastics in molding enterprises goes without saying. As we all know, molding is the manufacturing process by which a liquid or pliable new material obtains a rigid shape commonly known as a mold.

Plastic is characterized as a synthetically produced non-metallic compound that, most specifically, can be formed into various shapes and hardened for various commercial uses. That’s why plastic mold makers use plastic for their incredible plastic mold products. In simple terms, plastic molding is the process of molding plastic using a rigid frame or mold. By using this demanding plastic moulding technology, objects of various shapes and sizes can be designed with great flexibility. For example, it offers significant flexibility for simple and highly complex designs such as automotive parts, containers, signs and other high-volume items. Plastic molding is a very technical process.

Conceptually, the basic technique of plastic molding used by plastic mold suppliers is to insert molten liquid plastic into a molding mold. Then let it cool and remove the mold. No matter how many molding processes there are in plastic molding. These are – Injection Molding, Blow Molding, Compression Molding, Film Insert Molding, Gas Assisted Molding, Rotational Molding, Structural Foam Molding, Thermoforming, etc.

Welcome to choose us, choose us and you will not be disappointed.