About chair mold injection

Injection molding is a very versatile and incredibly useful manufacturing technique. It is most often used when working with plastics, but this process can also be used with other types of materials. Some of the other most commonly used materials for injection molding include various types of glass, elastic polymers, rubber, and even sugars. Some injection molded parts are made of more than one type of material and can also have metal hardware, although these involve extra steps in the process.

Injection molding design shares several similarities with die casting. It is frequently used alongside other manufacturing processes to create as many of the finished product’s components as possible. This process offers several advantages and is something that should at least be considered when planning to manufacture a new product. When large numbers of parts are needed, and they can be made of a moldable material, injection molding is often the best choice.

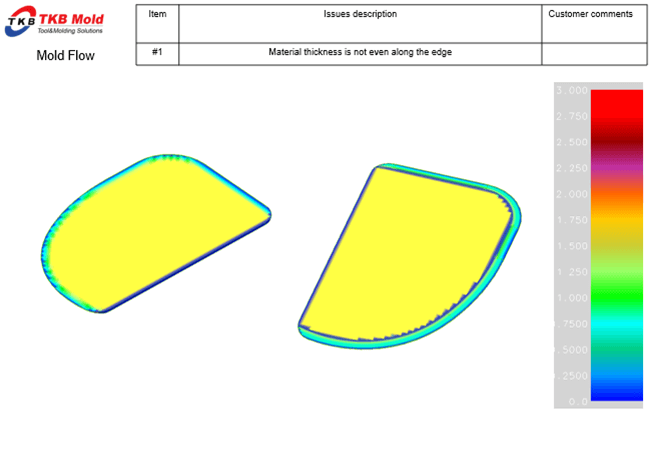

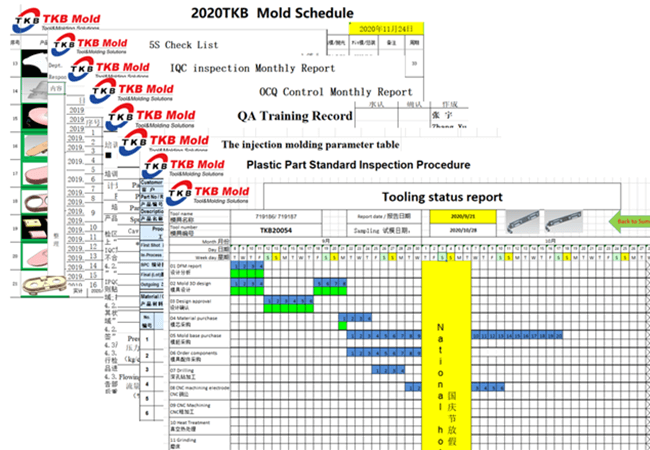

However, the injection molding process has its pitfalls, just like other types of manufacturing. Costs can become unnecessarily high if specific aspects of the project are left unchecked. Fortunately, there are numerous ways to control and reduce the cost of injection molding just from a design perspective. In addition to optimizing the design of parts and molds for this process, there are some other factors to consider that can help to reduce the production cost.

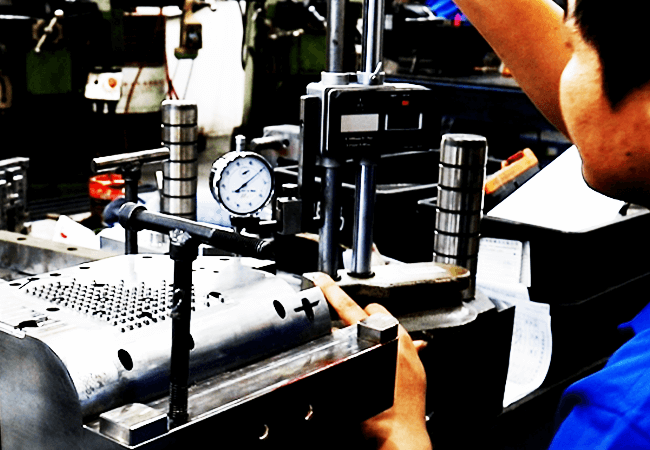

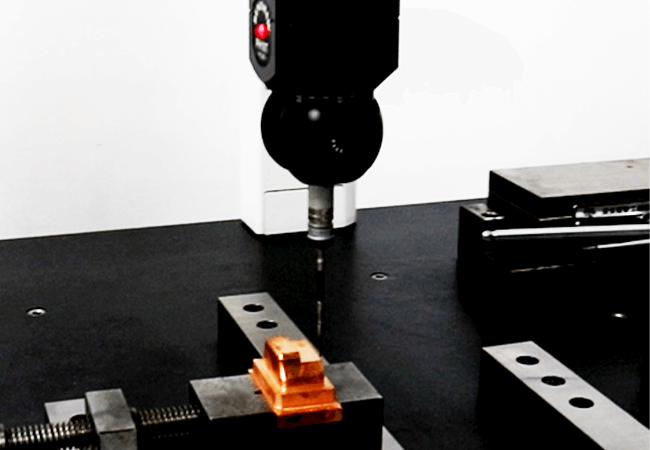

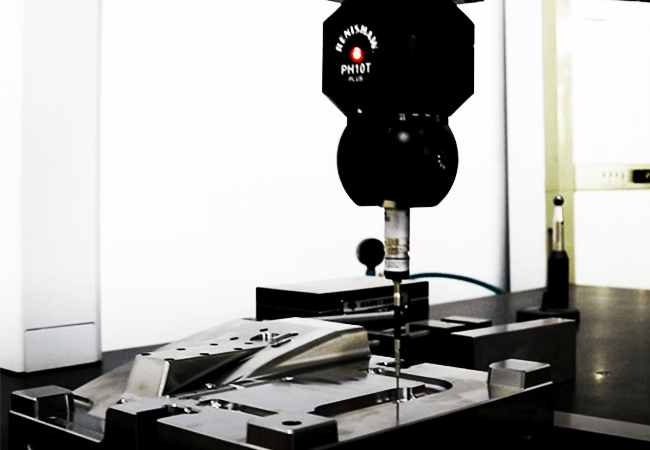

Molds that are used for this process may be made from several grades of tool steel. In some circumstances, they may be made of stainless steel or even aluminum. Which material is appropriate for the mold is determined by the material that will be flowing into it along with considerations like production volume, cost, and desired life expectancy of the mold.

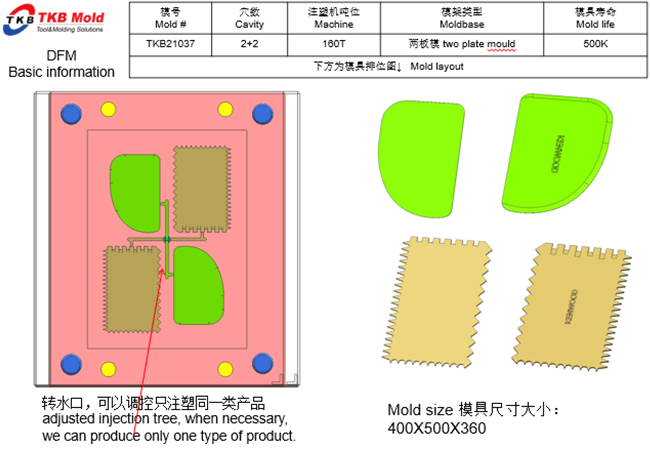

These molds often have multiple cavities to allow for the production of multiple pieces at the same time. This allows a single mold to produce multiples of the same part, a variety of different components, or even multiples of several parts from a single cycle.

The plastics and other materials used in injection molding are often in a bead or pellet form.