About plastic injection molding companies

Plastic injection molding is specifically designed for mass production of plastic parts by reusing the same mold. Consistent color, structure and appearance are the characteristics of injection molded parts. Hundreds of thousands of custom parts are produced by machines. The cost per part decreases with higher volume manufacturing runs.

The injection molding process is the preferred choice for high-volume production of plastic parts because of its repeatability, wide range of material options, low labor costs, high precision, and few complex post-processing steps.

Injection molding is the manufacturing process of producing parts by injecting molten material into a mold or mold. Injection molding can be done with a variety of materials, primarily metals (the process is called die casting), glass, elastomers, confectionery, and most commonly thermoplastic and thermoset polymers.

Why choose us

We are a mold making supplier with 15 years of experience, TKB can provide a one-stop service including prototyping, mold design, material selection, mold making, injection molding, logo printing, related parts procurement, assembly and packaging.

WHY CHOOSE TKB Injection Mold Manufacturing?

Your injection mold manufacturing makes your product from concept to reality?

Your injection mold is manufactured with the ideal precision?

Want custom plastic molds to without flashes and with durable mold die life?

Then start mold manufacturing at TKB Mold, and let’s creat an ideal injection mold solution for your product.

Out standing engineering team for export molds

Rich experience in mold fabrication

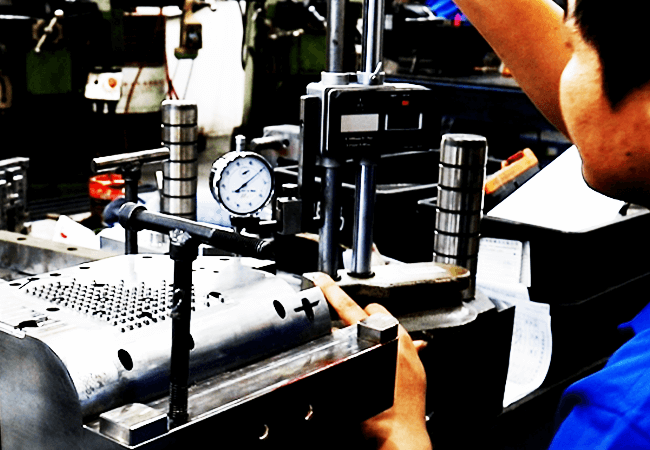

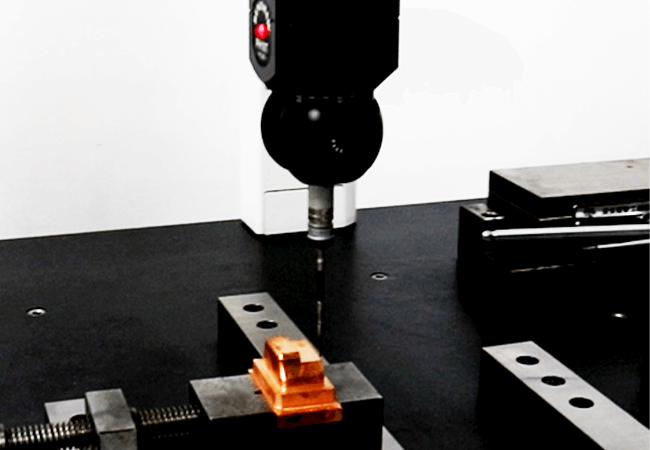

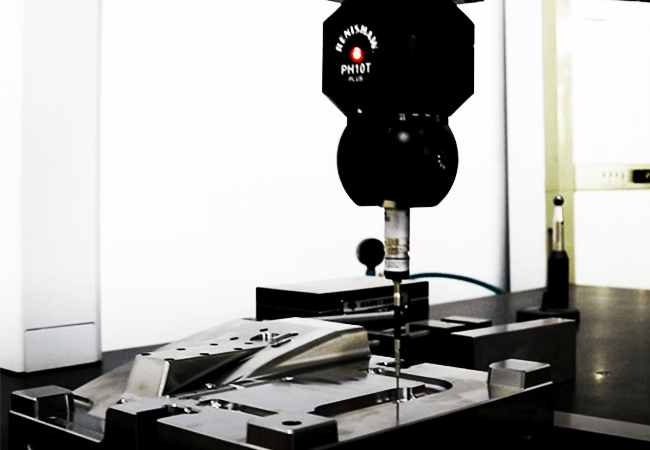

Advanced manufacturing equipment

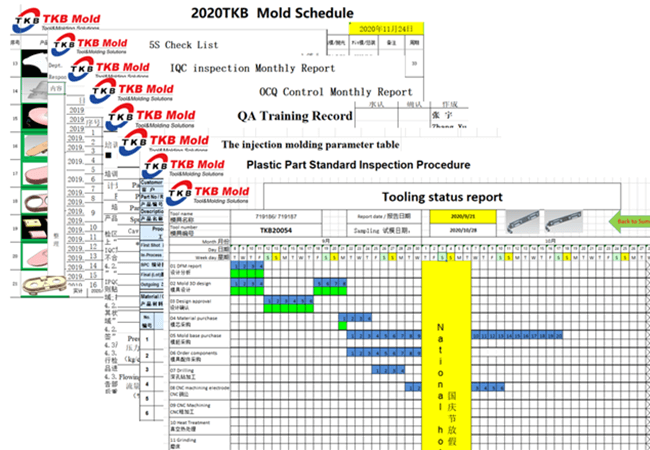

Quality assurance of ISO9001: 2015 system

Fast delivery time

Excellent after sales service

TKB Process for Injection Mold Manufacturing

To make a good quality export plastic injection mold, processes as below for your reference:

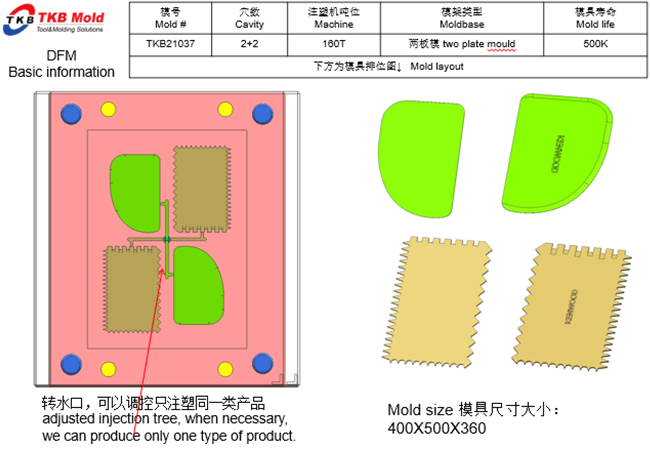

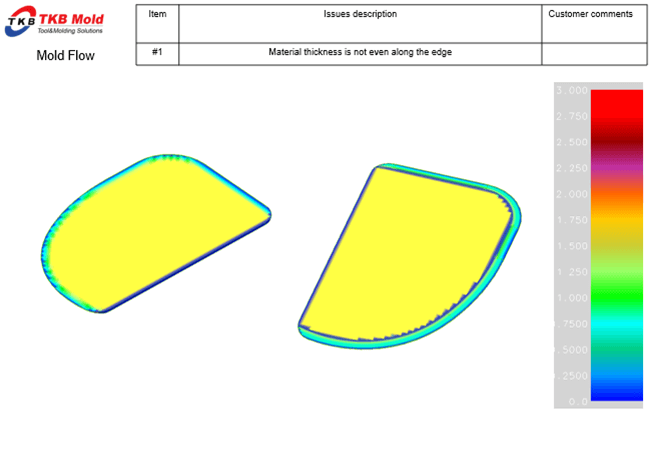

DFM Report, Mold Flow analysis, conclude 2D/3D Mold drawing, approval to mold fabrication.

Mold steel preparation—Processing—Mold Base Processing—-Electrodes Processing—-Mold Parts Processing—-Quality Control—–Mold Fitting and Assembly—Inspection—-Mold Trial—Mass Production Trial—Inspection PASS—Pack and export the Mold

TKB types of plastic injection mold

Since plastic injection mold is widely used for many industries, TKB mold has advantage for producing high precision injection molds as follows:

Automotive Mold +

Medical Mold +

Electronics Mold +

Home Appliance Mould +

Industrial Mold +

Aerospace Mold +

Overmold +

Precision Molds +