About plastic injection mold tooling

Casting system; clamping guide mechanism; molding parts; exhaust mechanism; product launch and reset mechanism; side core pulling mechanism; mold heating or cooling system;

The injection mold design is based on the actual situation of the plastic parts, and the design is carried out according to the above structure. Design an injection mold that can actually produce a composite plastic injection molding process that meets the requirements of use.

What are the differences between plastic injection molds and die-casting molds?

Die-casting mold cores do not need quenching, because the temperature in the mold cavity exceeds 100 degrees during die-casting. Therefore, each molding time is equivalent to quenching once, and the mold cavity will become harder and harder. The general injection mold should be quenched above, and the cavity of the die-casting mold should be nitrided to prevent the alloy from sticking to the mold cavity. Due to the relatively large corrosion of the die-casting mold, some customers require the outer surface of the mold to be blued.

WHY CHOOSE TKB Injection Mold Manufacturing?

Your injection mold manufacturing makes your product from concept to reality?

Your injection mold is manufactured with the ideal precision?

Want custom plastic molds to without flashes and with durable mold die life?

Then start mold manufacturing at TKB Mold, and let’s creat an ideal injection mold solution for your product.

Out standing engineering team for export molds

Rich experience in mold fabrication

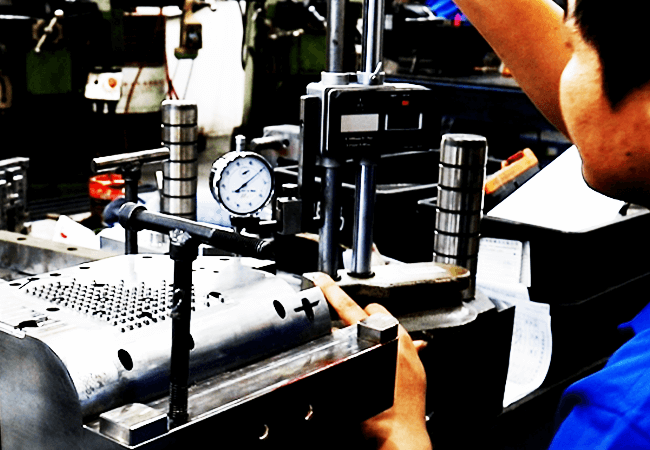

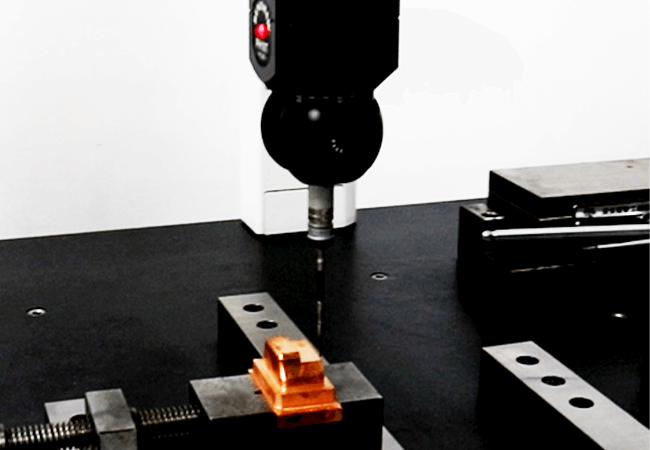

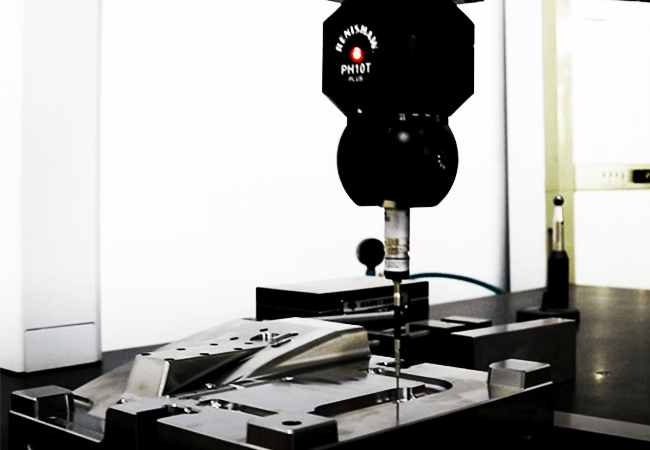

Advanced manufacturing equipment

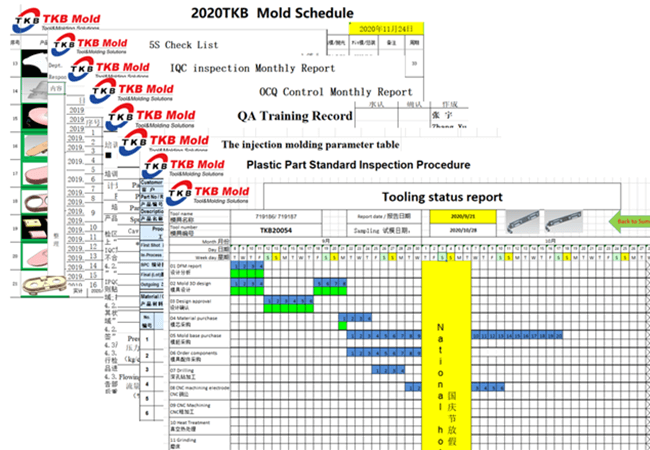

Quality assurance of ISO9001: 2015 system

Fast delivery time

Excellent after sales service

TKB Process for Injection Mold Manufacturing

To make a good quality export plastic injection mold, processes as below for your reference:

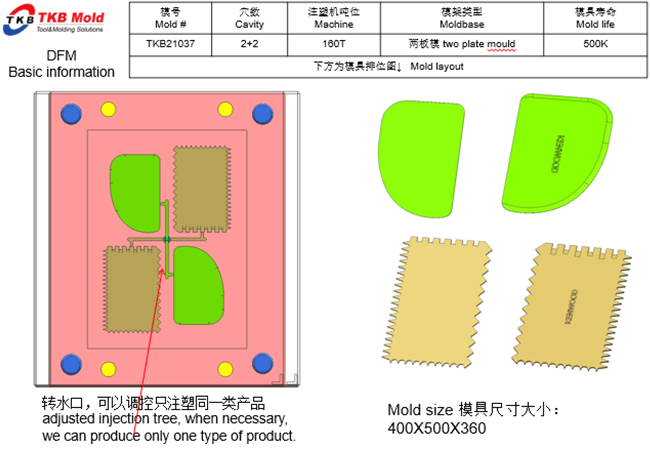

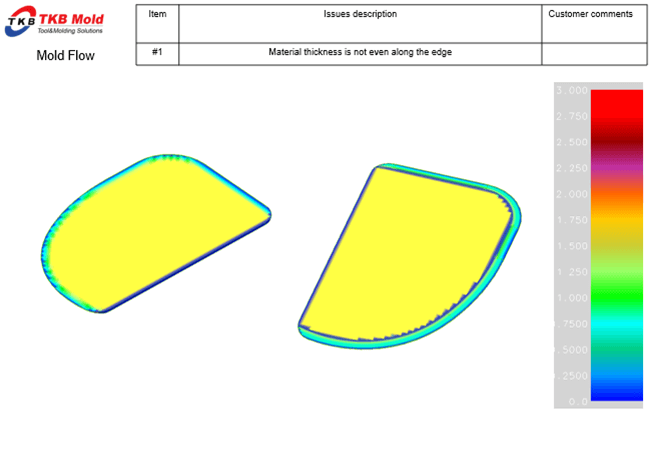

DFM Report, Mold Flow analysis, conclude 2D/3D Mold drawing, approval to mold fabrication.

Mold steel preparation—Processing—Mold Base Processing—-Electrodes Processing—-Mold Parts Processing—-Quality Control—–Mold Fitting and Assembly—Inspection—-Mold Trial—Mass Production Trial—Inspection PASS—Pack and export the Mold

TKB types of plastic injection mold

Since plastic injection mold is widely used for many industries, TKB mold has advantage for producing high precision injection molds as follows:

Automotive Mold +

Medical Mold +

Electronics Mold +

Home Appliance Mould +

Industrial Mold +

Aerospace Mold +

Overmold +

Precision Molds +