About custom mould

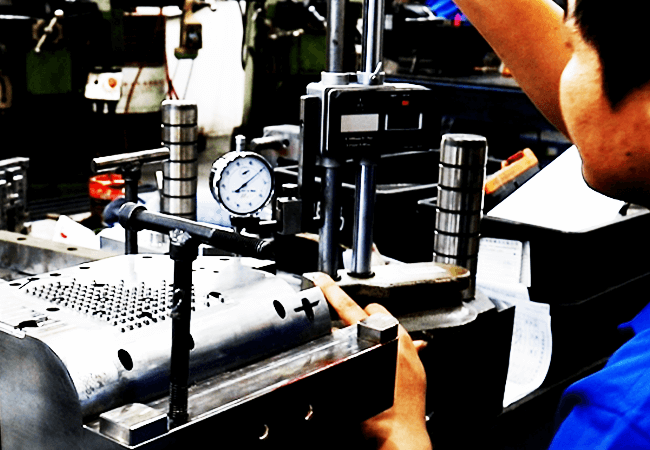

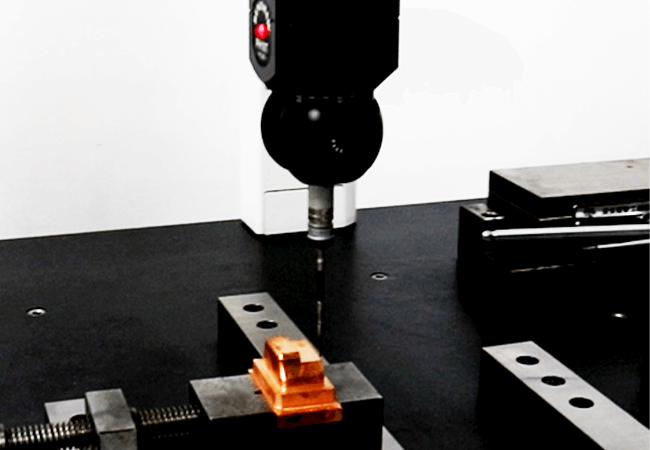

We are a leading manufacturer of injection molded plastics, including precision injection molded products, parts and assemblies. Manufactured from different plastics, resins, engineering resins and commodity resins with custom specific blends of masterbatches, additives, UV stabilizers and flame retardants.

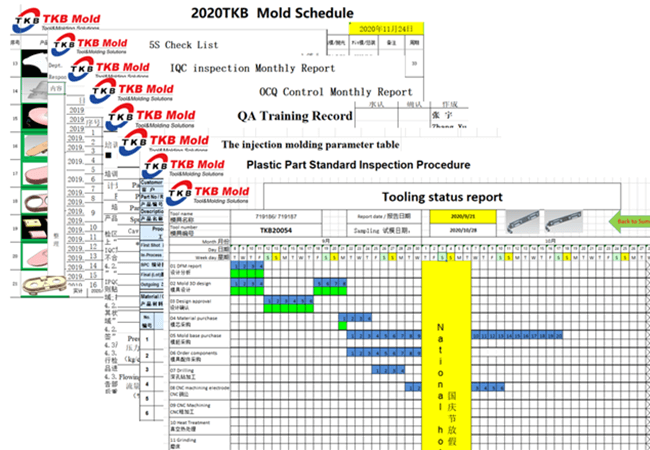

With 15 years of operating history, TKB provides exceptional service and exceptional quality that your company can rely on. Our products are also worthy of your trust.

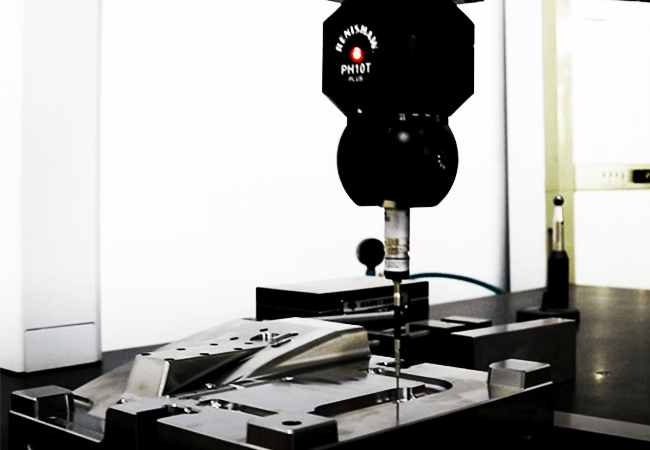

By using automation, moldmakers have been able to develop systems that interface with the ejector system very precisely and do not require an operator. There are many other points of view on the importance of good mold design to part productivity.

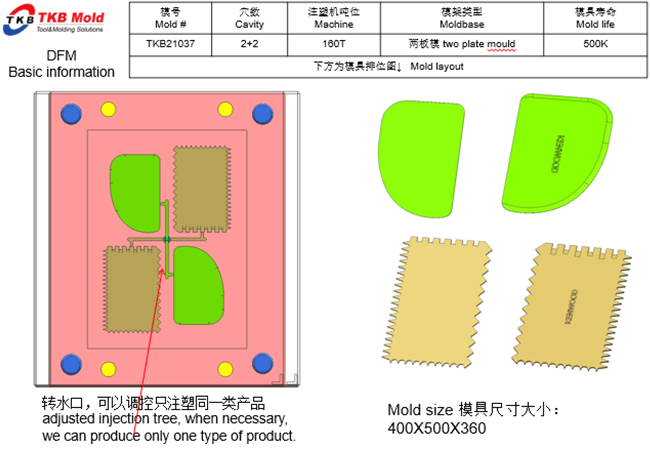

The importance of mold design to tool productivity is often overlooked in mold design. There are several areas in mold design that moldmakers must work with to optimize mold productivity. A good measure of mold productivity is parts sold per hour. Cycle time and part quality are key aspects of sellable parts per hour. The design areas most important to productivity are sprue bushings, runners and gates, hot manifolds, venting, cooling and ejection. While each of these items is specific to the mold being manufactured, a good design for each item can help improve part quality and optimize cycle times.

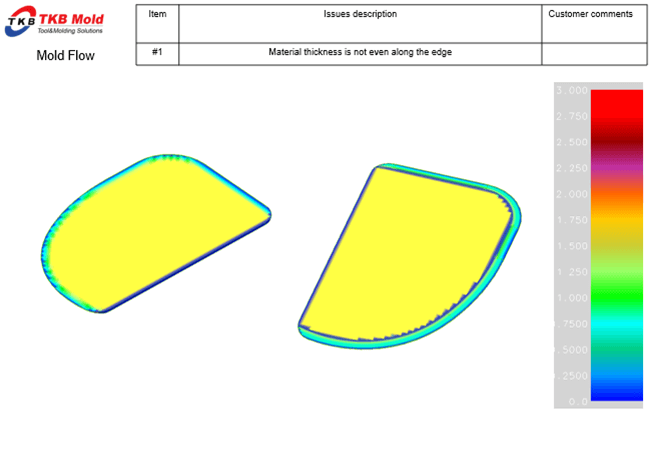

Features critical to mold design

The first and most important aspect of mold design is the size of the sprue bushing, runner, and gate. This standard is critical to ensuring parts can be stress-free filled, packaged and frozen for optimally formed parts. Using mold flow analysis and previous work by injection molding professionals, the correct size of gate bushings, runners, and gates can be determined with considerable accuracy for each molding material.